Delve into the realm of press brake tooling, where precision meets productivity in the art of sheet metal fabrication. This guide unlocks the intricacies of this essential component, empowering you with the knowledge to optimize your press brake operations and achieve exceptional results.

As we embark on this journey, we’ll explore the types, materials, and selection criteria for press brake tooling. We’ll delve into design considerations, manufacturing processes, and quality control measures to ensure the highest standards of performance and durability.

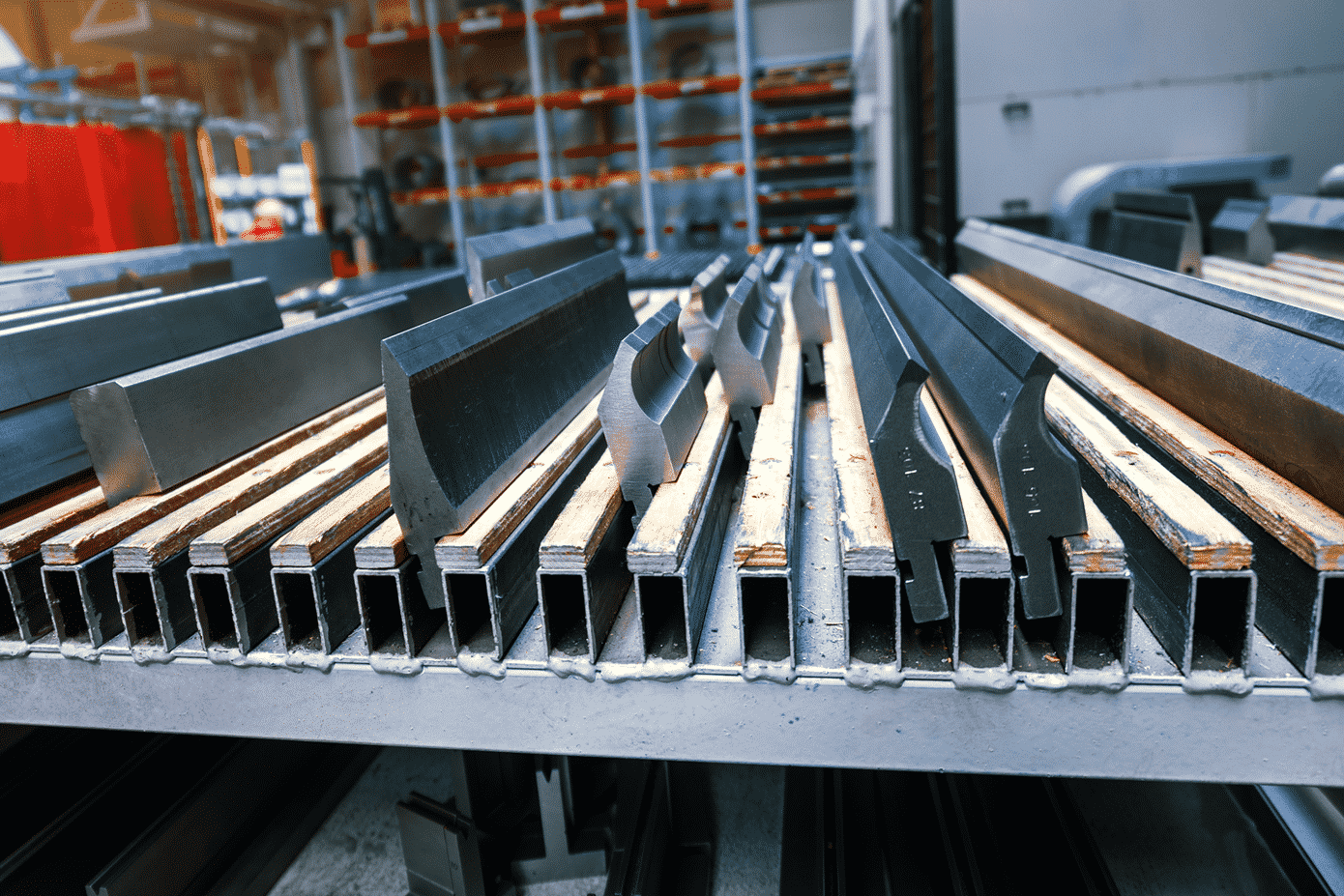

Press Brake Tooling Overview

Press brake tooling is a critical component of press brake machines, enabling them to bend and shape metal sheets into desired forms. It consists of a punch and die, which work together to apply pressure and form the metal. The selection of the right tooling is crucial to achieve precise and efficient bending operations.

There are various types of press brake tooling available, each designed for specific bending applications. The most common types include:

- V-dies and punches: These are the most basic type of tooling, used for simple bending operations. The V-shaped die provides support for the metal sheet, while the punch applies pressure to bend it.

- U-dies and punches: U-dies are similar to V-dies, but they have a wider opening. This allows for bending thicker materials or creating bends with larger radii.

- Gooseneck dies and punches: Gooseneck dies have a long, narrow neck that extends beyond the die opening. This allows for bending complex shapes, such as boxes or channels.

- Air bending dies and punches: Air bending dies use compressed air to hold the metal sheet in place during bending. This prevents the sheet from slipping or buckling, resulting in more precise bends.

The materials used in press brake tooling also play a crucial role in their performance and durability. The most common materials include:

- Tool steel: Tool steel is a high-carbon steel that is hardened and tempered to achieve high strength and wear resistance. It is commonly used for punches and dies that are subjected to high loads.

- Alloy steel: Alloy steel is a type of steel that contains additional elements, such as chromium or molybdenum, to improve its strength and toughness. It is often used for dies that require high wear resistance.

- Carbide: Carbide is an extremely hard material that is used for punches and dies that need to withstand extreme wear. It is commonly used in high-volume bending applications.

Press Brake Tooling Selection

Choosing the right press brake tooling is crucial for achieving optimal bending results. Several factors influence the selection process, and understanding these factors will help you make informed decisions.

Press brake tooling is essential for shaping metal sheets into desired forms. If you’re looking for a tool to add volume and style to your hair, consider the voloom hair tool. Its innovative design creates instant volume without heat damage.

Similarly, press brake tooling allows you to bend and form metal precisely, creating complex shapes with ease.

The primary considerations when selecting press brake tooling include the material being bent, the thickness of the material, the bend radius required, and the press brake machine’s capacity.

Material Compatibility

The material being bent determines the type of tooling required. Different materials have varying properties, such as strength, ductility, and hardness, which affect the tooling selection.

- Mild steel is the most common material bent in press brakes and requires standard tooling.

- Stainless steel is harder and more abrasive than mild steel, necessitating tooling with higher wear resistance.

- Aluminum is a soft material that requires tooling with a sharp cutting edge to prevent tearing.

Press Brake Tooling Design

Press brake tooling design involves careful consideration of several factors to ensure optimal performance and part quality. Computer-aided design (CAD) and finite element analysis (FEA) play significant roles in the design process, enabling engineers to optimize tooling geometry and predict its behavior under various operating conditions.

Design Considerations

- Material selection:The choice of material for the tooling depends on the material being formed, the desired bend radius, and the tooling life required.

- Tooling geometry:The geometry of the tooling, including the punch and die profiles, determines the shape and accuracy of the bend.

- Clearance between punch and die:The clearance between the punch and die affects the material flow and the bend quality.

- Tooling strength and rigidity:The tooling must be strong and rigid enough to withstand the forces involved in the bending process.

Use of Computer-Aided Design (CAD)

CAD software allows engineers to create detailed 3D models of press brake tooling. These models can be used to visualize the tooling geometry, check for interferences, and simulate the bending process.

Role of Finite Element Analysis (FEA)

FEA is a computer-based technique used to analyze the stress and strain distribution within the tooling under various operating conditions. This information helps engineers identify potential failure points and optimize the tooling design to improve its performance and longevity.

Press Brake Tooling Manufacturing

Press brake tooling manufacturing involves a series of precise processes to create high-quality tooling components. The manufacturing process typically includes several steps, such as raw material selection, design engineering, precision machining, heat treatment, grinding, and quality control.

Manufacturing Techniques, Press brake tooling

Various manufacturing techniques are employed to create press brake tooling, including:

CNC Machining

Computer Numerical Control (CNC) machining uses computer-controlled machines to precisely cut and shape tooling components from raw materials.

Wire EDM

Wire Electrical Discharge Machining (EDM) uses a thin wire electrode to cut complex shapes in hardened materials.

Grinding

Grinding is used to achieve precise dimensions and surface finishes on tooling components.

Heat Treatment

Heat treatment processes, such as hardening and tempering, are applied to enhance the strength and durability of tooling components.

When working with press brake tooling, it’s important to have the right tools for the job. A mac tool cart can be a great way to keep your tools organized and within reach. This type of cart is typically made of durable materials and features multiple drawers and compartments, making it easy to store and transport your press brake tooling.

Press Brake Tooling Applications

Press brake tooling is widely used in various industries for shaping and forming metal sheets. These tools are designed to work with press brakes, which are machines that apply force to bend or form metal sheets into desired shapes.

The versatility of press brake tooling makes it suitable for a range of applications, including:

Automotive Industry

- Manufacturing car body panels, chassis components, and other structural parts.

- Press brake tooling is highly efficient in producing complex shapes and bends required in automotive parts.

Aerospace Industry

- Creating aircraft components such as wings, fuselage panels, and engine nacelles.

- The aerospace industry demands high precision and accuracy, which press brake tooling can provide.

Construction Industry

- Producing roofing panels, siding, and other building components.

- Press brake tooling enables the creation of durable and weather-resistant metal structures.

Appliance Industry

- Manufacturing refrigerator doors, oven panels, and other appliance components.

- Press brake tooling helps achieve the precise bends and shapes needed for functional and visually appealing appliances.

Advantages of Press Brake Tooling

- Versatility: Can handle a wide range of metal forming applications.

- Precision: Produces accurate and consistent bends.

- Efficiency: Automates the bending process, saving time and labor.

- Durability: Built to withstand heavy-duty use.

Limitations of Press Brake Tooling

- Cost: Press brake tooling can be expensive to purchase and maintain.

- Complexity: Requires skilled operators to set up and operate.

- Material limitations: Not suitable for all types of metals or thicknesses.

Safety Considerations for Press Brake Tooling

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Ensure the press brake is properly maintained and inspected regularly.

- Follow proper operating procedures and avoid overloading the machine.

- Never attempt to clear jams or make adjustments while the machine is running.

FAQ Resource: Press Brake Tooling

What is the purpose of press brake tooling?

Press brake tooling enables the precise bending and forming of sheet metal, transforming flat sheets into complex shapes.

How do I choose the right press brake tooling for my application?

Consider factors such as material thickness, bend radius, and desired accuracy when selecting press brake tooling.

What are the benefits of using high-quality press brake tooling?

High-quality tooling ensures precise bends, reduces downtime, and extends the lifespan of your press brake.