In the realm of manufacturing, injection molding tools reign supreme, shaping intricate parts with unparalleled precision. These tools, the cornerstone of injection molding, transform molten plastic into a myriad of products, from automotive components to medical devices. Dive into the world of injection molding tools, where innovation and engineering converge to create the objects that shape our daily lives.

From core and cavity molds to stack and family molds, each type of injection molding tool offers unique advantages and applications. Understanding their design considerations, manufacturing processes, and maintenance techniques is crucial for optimizing production efficiency and ensuring product quality.

Introduction

Injection molding tools play a crucial role in the manufacturing industry, enabling the production of a wide range of plastic parts. These tools are designed to shape molten plastic into specific configurations, creating products with intricate details and precise dimensions.

There are various types of injection molding tools, each tailored to specific applications. The most common types include:

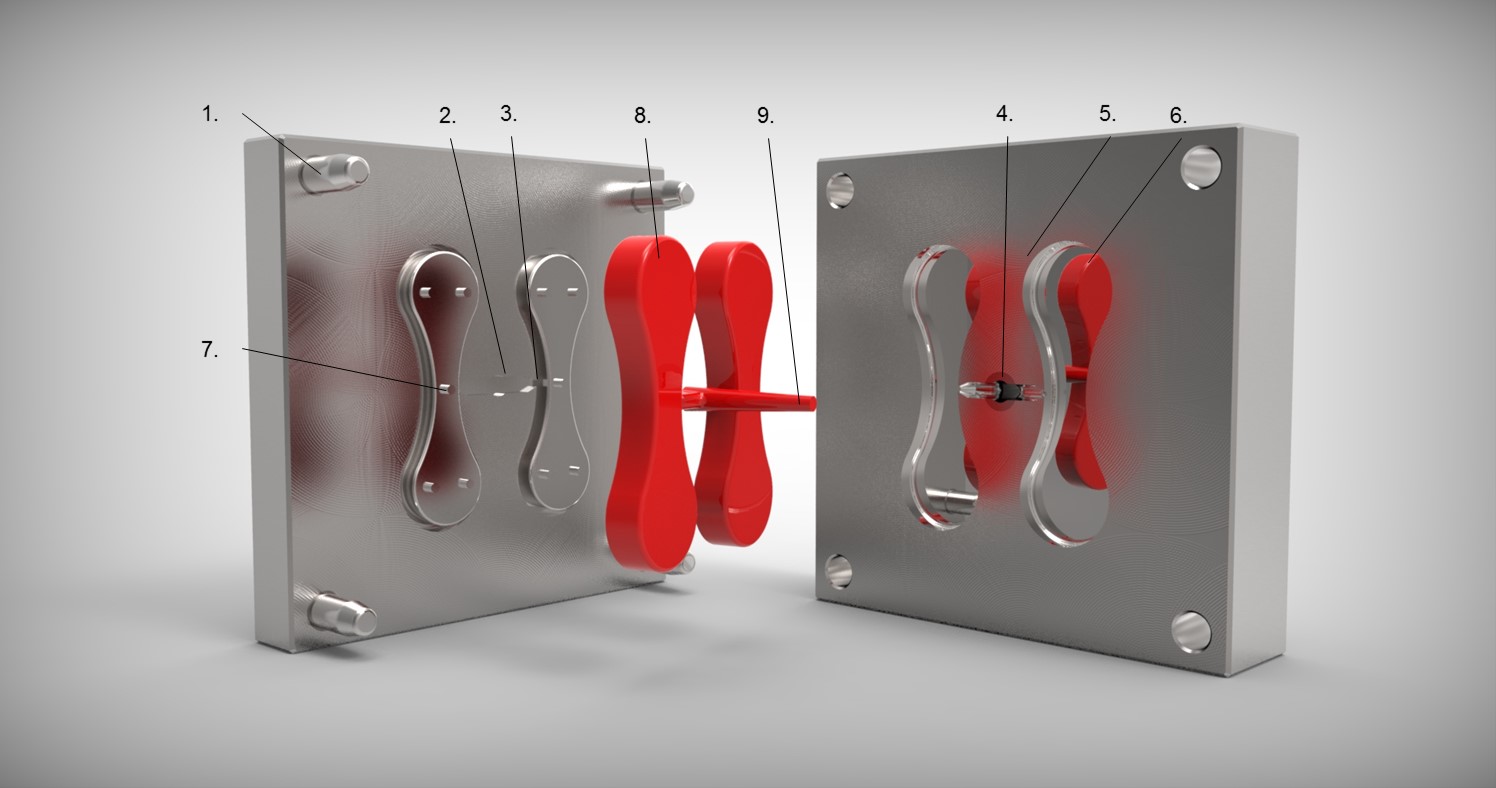

- Molds:These are the primary tools used in injection molding, consisting of two halves that clamp together to form the desired shape of the plastic part.

- Cores and Cavities:Cores create internal cavities or holes within the plastic part, while cavities define the external shape.

- Sprue and Runners:The sprue is the channel through which molten plastic enters the mold, while runners distribute the plastic to different cavities.

- Ejectors:These mechanisms push the finished plastic part out of the mold after it has cooled.

The injection molding process involves several key steps:

- Molten plastic is injected into the mold cavity under high pressure.

- The plastic cools and solidifies, taking the shape of the mold.

- The mold opens, and the finished part is ejected.

Types of Injection Molding Tools

Injection molding tools are essential for producing plastic parts. There are various types of injection molding tools, each with its own advantages and disadvantages. The type of tool used will depend on the specific part being produced.

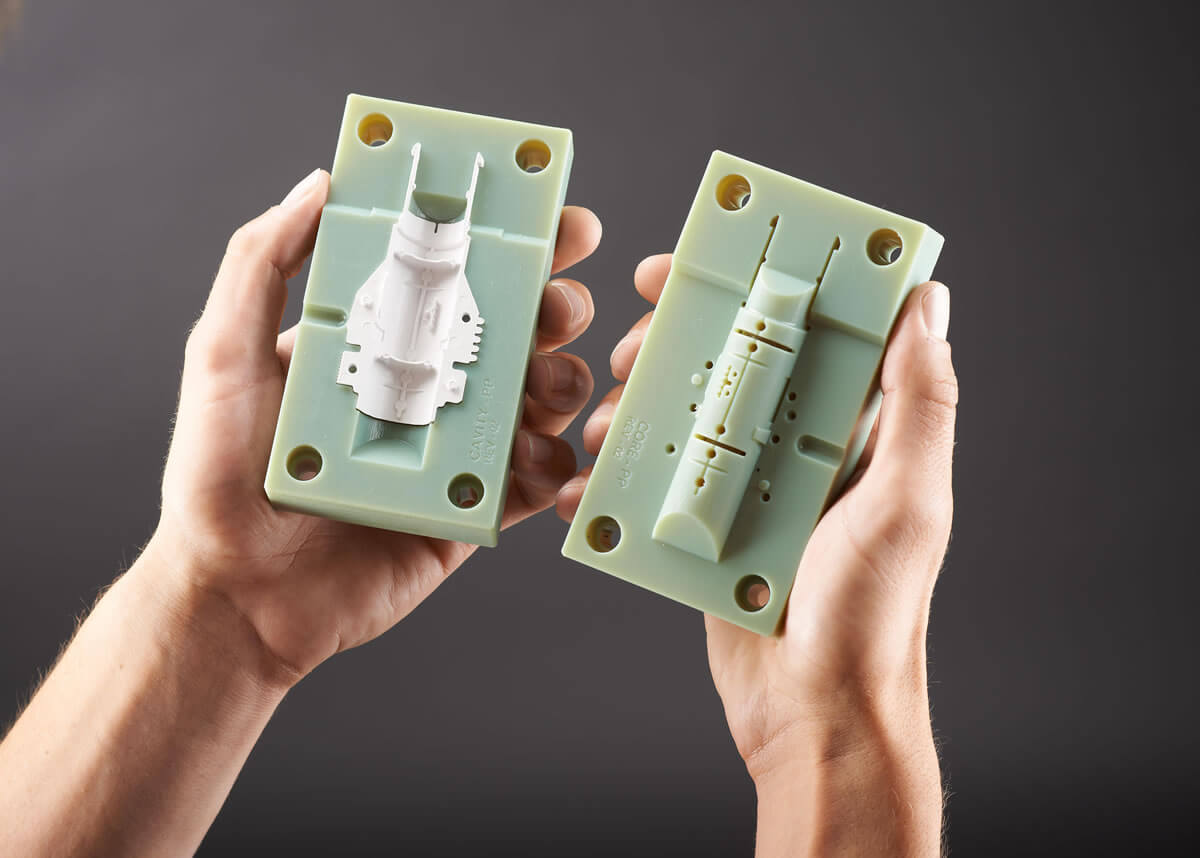

Core and Cavity Molds

Core and cavity molds are the most common type of injection molding tool. They consist of two main components: the core, which forms the inside of the part, and the cavity, which forms the outside of the part. Core and cavity molds are relatively simple to design and manufacture, and they can produce high-quality parts.

Injection molding tools are crucial for the production of plastic parts. If you’re interested in understanding how these tools can be used in the context of electronic design, check out the eddm mapping tool. This tool provides insights into the integration of injection molding techniques in electronic designs.

Whether you’re a designer or an engineer working with injection molding tools, this resource can enhance your understanding of their applications in electronic design.

However, they are not suitable for producing parts with complex geometries or undercuts.

Insert Molds

Insert molds are used to produce parts with metal inserts. The inserts are placed into the mold before the plastic is injected. This allows for the production of parts with complex geometries or undercuts. Insert molds are more complex to design and manufacture than core and cavity molds, but they can produce high-quality parts with complex features.

Stack Molds

Stack molds are used to produce parts with multiple cavities. The cavities are stacked on top of each other, which allows for the production of multiple parts in a single cycle. Stack molds are more complex to design and manufacture than core and cavity molds, but they can be more efficient for producing large quantities of parts.

Family Molds

Family molds are used to produce a family of parts in a single cycle. The parts are all related, but they have different sizes or shapes. Family molds are more complex to design and manufacture than core and cavity molds, but they can be more efficient for producing a family of parts.

Design Considerations for Injection Molding Tools

Effective injection molding tools require careful design to ensure optimal performance and product quality. Several key considerations must be taken into account during the design process, including material selection, gate design, ejection system design, and cooling system design.

These design considerations are crucial for achieving efficient and precise injection molding operations, ensuring the production of high-quality plastic parts that meet specific requirements.

Material Selection

The choice of material for injection molding tools is critical as it directly impacts the tool’s durability, wear resistance, and overall performance. Common materials used include:

- Tool steel: Known for its high strength, hardness, and wear resistance, making it suitable for high-volume production.

- Aluminum: Offers good thermal conductivity and machinability, but has lower strength and wear resistance than tool steel.

- Beryllium copper: Provides excellent thermal conductivity and wear resistance, often used in applications requiring high precision and rapid cooling.

The specific material selection depends on the desired tool life, production volume, and the properties of the plastic being molded.

Gate Design

The gate is the entry point for molten plastic into the mold cavity. Its design influences the flow pattern, pressure distribution, and overall part quality.

- Sprue gate: A simple and widely used gate design, where the molten plastic enters the mold through a central sprue.

- Edge gate: Plastic enters the mold cavity through a gate located at the edge of the part, reducing shear stress and improving part surface finish.

- Submarine gate: The gate is submerged below the surface of the part, eliminating visible gate marks.

The choice of gate design depends on factors such as part geometry, material properties, and desired flow characteristics.

Ejection System Design

The ejection system is responsible for removing the molded part from the mold cavity. Proper design ensures efficient ejection and prevents part damage.

- Ejector pins: Metal pins that push the part out of the mold cavity.

- Ejector blades: Thin, flexible blades that slide under the part to eject it.

- Stripper plates: Plates that move the part away from the mold after ejection.

The design of the ejection system considers factors such as part geometry, ejection force required, and the need for secondary operations.

Injection molding tools, essential for manufacturing plastic parts, require precise monitoring to ensure optimal performance. Consider using a hand hygiene audit tool to maintain the cleanliness of the production area and prevent contamination. By integrating this tool into your injection molding process, you can ensure the quality and safety of your products.

Cooling System Design

The cooling system removes heat from the mold to solidify the molten plastic and reduce cycle time. Effective cooling ensures dimensional stability and prevents part defects.

- Water cooling: Channels or passages within the mold are circulated with water to absorb heat.

- Air cooling: Air is blown over the mold surface to dissipate heat.

- Vacuum cooling: A vacuum is applied to the mold cavity to accelerate cooling.

The cooling system design depends on the size and complexity of the mold, the material being molded, and the desired cycle time.

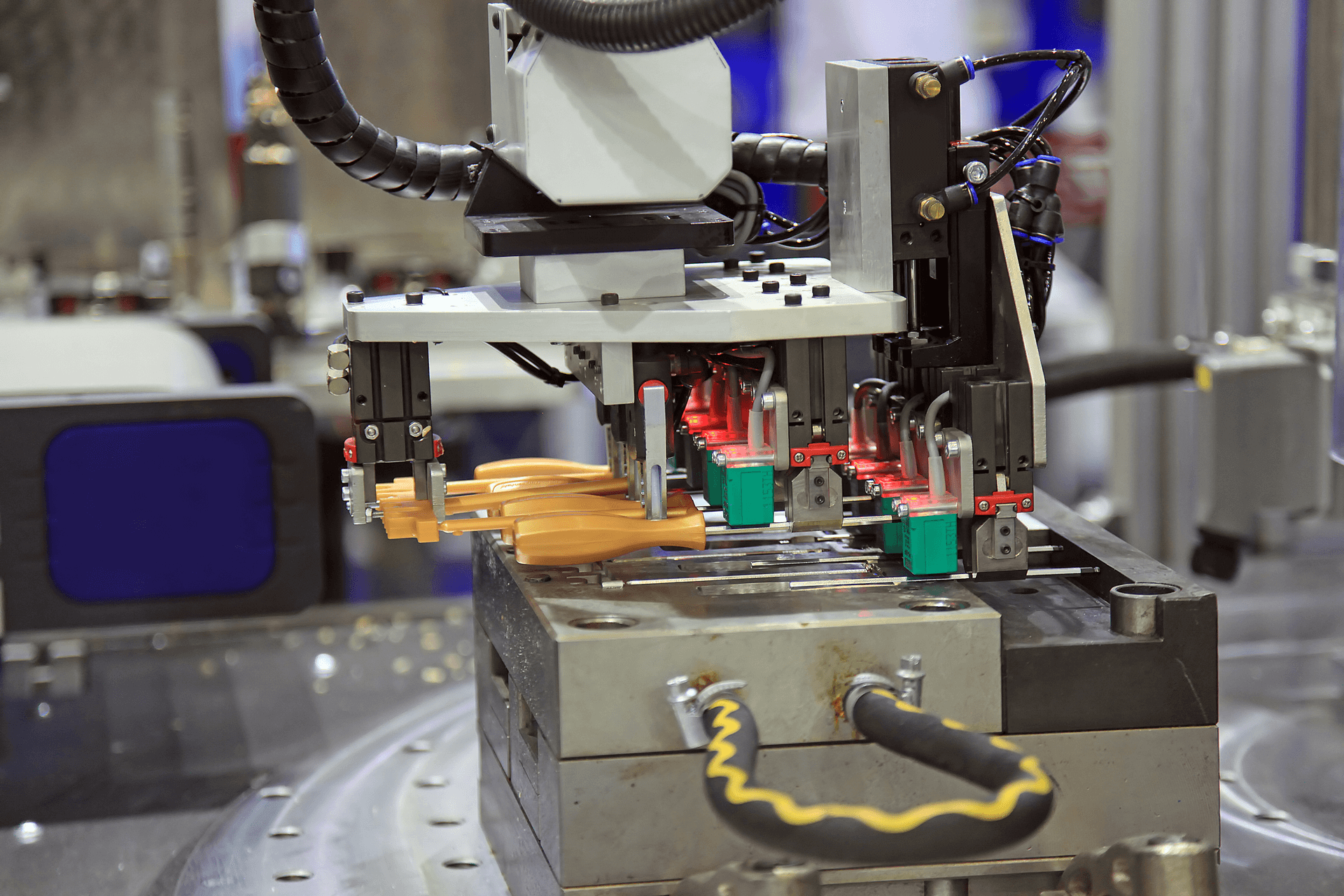

Manufacturing Processes for Injection Molding Tools

Injection molding tools are essential for the production of plastic parts. These tools are used to create the mold cavity that gives the plastic part its shape. There are a variety of manufacturing processes that can be used to create injection molding tools, each with its own advantages and disadvantages.

The most common manufacturing process for injection molding tools is CNC machining. CNC machining uses a computer-controlled cutting tool to remove material from a block of metal, creating the desired mold cavity. CNC machining is a precise and versatile process that can be used to create complex shapes.

However, it can be time-consuming and expensive.

Another common manufacturing process for injection molding tools is EDM (Electrical Discharge Machining). EDM uses a spark to erode material from a block of metal, creating the desired mold cavity. EDM is a precise process that can be used to create complex shapes.

However, it can be slow and expensive.

Wire EDM, Injection molding tools

Wire EDM is a type of EDM that uses a thin wire electrode to cut through metal. Wire EDM is a precise process that can be used to create complex shapes. It is also faster and less expensive than traditional EDM.

Sinker EDM

Sinker EDM is a type of EDM that uses a shaped electrode to create the desired mold cavity. Sinker EDM is a precise process that can be used to create complex shapes. It is also faster and less expensive than traditional EDM.

Maintenance and Repair of Injection Molding Tools

Maintaining and repairing injection molding tools is crucial for ensuring their optimal performance and longevity. Proper care can minimize downtime, reduce production costs, and enhance product quality.

Cleaning and Inspection

Regular cleaning and inspection are essential for maintaining injection molding tools. Cleaning removes dirt, debris, and contaminants that can affect tool performance. Inspection identifies potential issues such as wear, damage, or corrosion.

Troubleshooting Common Problems

Common problems with injection molding tools include flow lines, short shots, and flash. Flow lines are caused by uneven material flow, while short shots occur when the mold cavity is not completely filled. Flash refers to excess material that escapes from the mold.

Repairing Damaged Tools

Damaged injection molding tools require prompt repair to prevent further damage and ensure continued operation. Repairs can involve welding, grinding, or replacing damaged components. Proper repair techniques and materials are essential for restoring tool functionality.

Applications of Injection Molding Tools

Injection molding tools are widely used in various industries, producing a diverse range of products with intricate designs and precise dimensions. Here are some of the key industries that utilize injection molding tools:

Automotive Industry

Injection molding is extensively used in the automotive industry for manufacturing components such as dashboards, bumpers, interior panels, and other plastic parts. These parts require high precision, durability, and aesthetic appeal, which injection molding can effectively achieve.

Medical Industry

Injection molding plays a crucial role in the medical industry, producing medical devices, implants, and other components. These products demand high levels of sterility, biocompatibility, and precision, which injection molding can provide.

Electronics Industry

Injection molding is widely used in the electronics industry to manufacture components such as circuit boards, connectors, and enclosures. These parts require precise dimensions, electrical insulation, and durability, which injection molding can ensure.

Aerospace Industry

The aerospace industry utilizes injection molding to produce lightweight and high-strength components for aircraft and spacecraft. These parts must meet stringent requirements for weight reduction, durability, and reliability, which injection molding can fulfill.

FAQ Guide

What are the key factors to consider when designing injection molding tools?

Material selection, gate design, ejection system design, and cooling system design are all crucial factors to optimize tool performance and product quality.

What are the advantages of using CNC machining for manufacturing injection molding tools?

CNC machining offers high precision, versatility, and the ability to create complex geometries, making it ideal for producing intricate mold components.

How can I ensure the longevity of my injection molding tools?

Regular cleaning, inspection, and proper maintenance practices, including troubleshooting and repairing common problems, are essential for extending tool life and maintaining optimal performance.