How to fix rod knock? It’s a question that every car enthusiast dreads hearing. Rod knock is a serious engine problem that can be a real pain in the neck, and it can quickly turn into a major headache if not addressed promptly.

It’s that loud knocking sound that makes you cringe and think, “Oh no, what have I done?” But fear not, my fellow gearheads, because we’re here to break down this common engine issue and equip you with the knowledge you need to tackle it head-on.

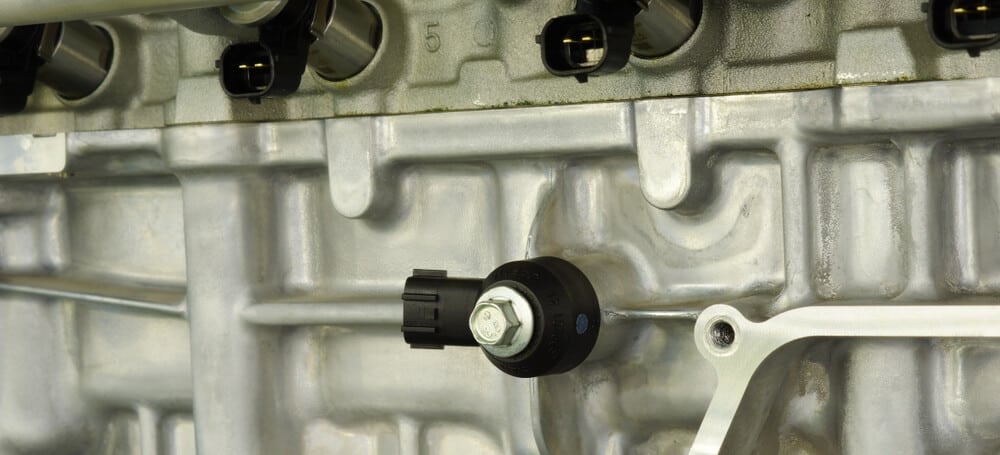

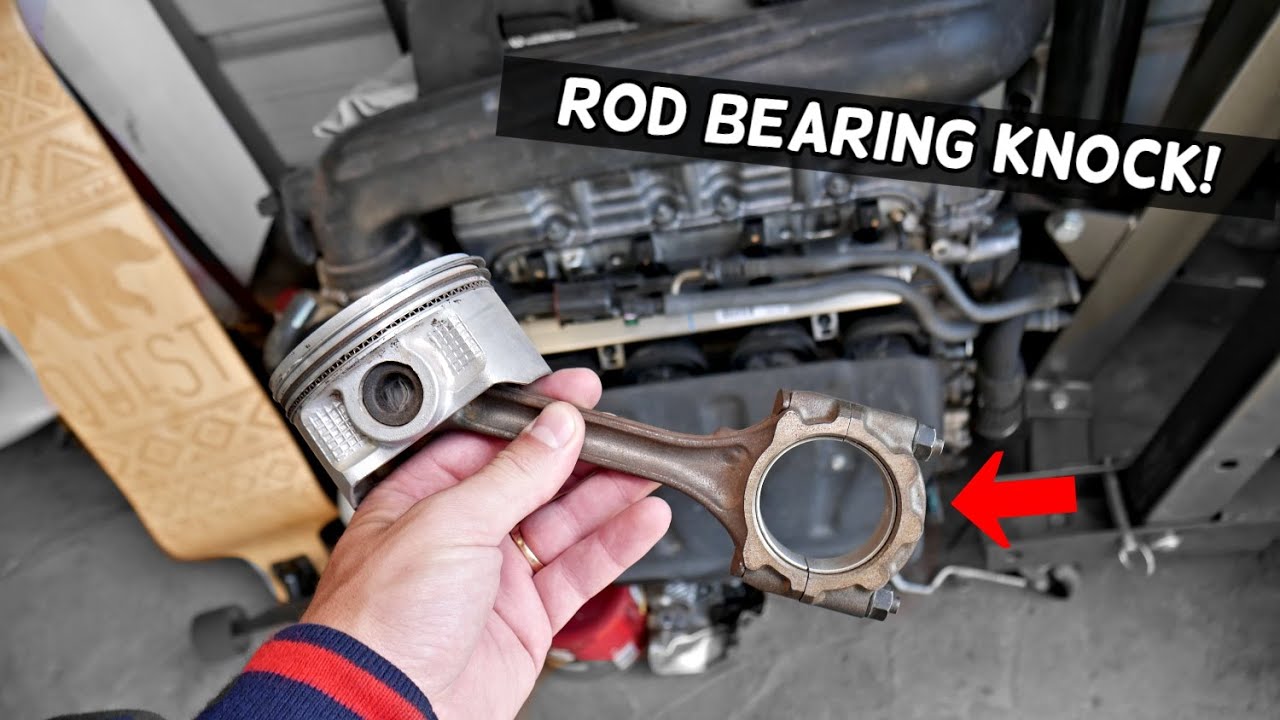

Rod knock is essentially a symptom of a worn-out or damaged connecting rod bearing, which is a crucial component in your engine’s inner workings. Imagine it like the tiny, hardworking hero that keeps your engine’s pistons moving smoothly. When this bearing starts to go bad, it can cause a knocking sound that gets louder and more noticeable as the problem worsens.

And if you ignore it, it can lead to major engine damage, leaving you stranded and with a hefty repair bill.

Understanding Rod Knock

Rod knock is a serious engine problem that can lead to catastrophic engine failure if not addressed promptly. It’s characterized by a distinctive knocking sound that emanates from the engine, often accompanied by other symptoms like engine vibration and reduced power.

Understanding the causes, symptoms, and potential consequences of rod knock is crucial for any car owner.

The Mechanism of Rod Knock

Rod knock occurs when the connecting rod bearings, which connect the connecting rod to the crankshaft, become worn or damaged. This can happen due to various reasons, including wear and tear, improper lubrication, or engine overheating. The connecting rod bearings are responsible for reducing friction between the connecting rod and the crankshaft, allowing the engine to run smoothly.

When these bearings fail, the connecting rod starts to knock against the crankshaft, creating the characteristic knocking sound.

Symptoms of Rod Knock, How to fix rod knock

The most common symptom of rod knock is a loud knocking sound that originates from the engine. The sound is often described as a “metallic clanging” or “rattling” noise. The severity of the knocking sound can vary depending on the extent of the damage to the connecting rod bearings.

- The sound of rod knock typically increases in frequency and intensity as the engine speed increases.This is because the connecting rod is moving faster at higher engine speeds, resulting in more frequent and forceful impacts against the crankshaft.

- The sound may also change with engine load.For example, the knocking sound may be more pronounced when the engine is under heavy load, such as when accelerating or towing.

- Other symptoms of rod knock include engine vibration, loss of power, and increased oil consumption.These symptoms occur because the damaged connecting rod bearings allow oil to leak into the combustion chamber, reducing engine efficiency and causing damage to other engine components.

Causes of Rod Knock

Rod knock can be caused by a number of factors, including:

- Worn connecting rod bearings:Over time, the connecting rod bearings can wear down due to friction and heat. This wear can lead to gaps between the bearings and the crankshaft, causing the connecting rod to knock against the crankshaft.

- Improper lubrication:If the engine oil is not properly lubricating the connecting rod bearings, they can overheat and fail prematurely. This can be caused by a number of factors, such as using the wrong type of oil, not changing the oil regularly, or having a clogged oil filter.

- Engine overheating:When the engine overheats, the connecting rod bearings can expand and seize, causing them to fail. This can happen if the cooling system is not working properly or if the engine is being overworked.

Key Points About Rod Knock

Rod knock is a serious engine problem that can result in catastrophic engine failure if left untreated. It is characterized by a distinctive knocking sound that originates from the engine, often accompanied by other symptoms like engine vibration, reduced power, and increased oil consumption.

The primary cause of rod knock is the failure of connecting rod bearings, which can be caused by factors like wear and tear, improper lubrication, or engine overheating. Prompt attention to rod knock is essential to prevent further damage and costly repairs.

Diagnosing Rod Knock

Rod knock, a telltale sign of engine trouble, is a rhythmic knocking sound that emanates from the engine, indicating a serious problem within the connecting rod assembly. This guide will equip you with the knowledge and techniques to diagnose rod knock effectively, helping you identify the issue and take appropriate action.

Understanding Rod Knock

Rod knock occurs when the connecting rod bearings, responsible for connecting the crankshaft to the piston, wear down or become damaged. This wear causes excessive clearance between the bearing surfaces, resulting in a knocking sound as the piston and connecting rod move back and forth.

The severity of rod knock can vary, ranging from a faint tapping noise to a loud, metallic bang, indicating significant damage.

Symptoms of Rod Knock, How to fix rod knock

Rod knock is typically characterized by a rhythmic knocking sound that intensifies with engine speed. The sound is often described as a “clicking” or “tapping” noise, and it can be heard most prominently when the engine is accelerating or decelerating.

Fixing rod knock is a bit like trying to put lipstick on a pig – it might look better, but the underlying issue is still there. If you’re dealing with deep scratches on your Ray Bans, though, you might be in luck! Check out how to fix deep scratches in ray bans for some tips.

As for that rod knock, well, maybe you should just start saving up for a new engine – you know, like a fresh pair of shades after a good scratch.

Vibrations within the engine compartment can also be a symptom, particularly at higher RPMs.

Severity of Rod Knock

Rod knock is a progressive condition that worsens over time. In its early stages, the noise may be subtle and only noticeable at high engine speeds. However, as the damage progresses, the knocking sound becomes louder and more pronounced, even at idle.

Eventually, the rod bearings can fail completely, leading to catastrophic engine damage, including piston seizure and crankshaft damage.

Diagnosing Rod Knock

Diagnosing rod knock involves a combination of visual inspection, sound analysis, compression testing, and engine vibration assessment.

Visual Inspection

A visual inspection can provide clues about the condition of the engine and potential signs of rod knock. Look for oil leaks, excessive wear on engine components, or loose components. Pay particular attention to the oil pan and valve cover, as they may show signs of oil contamination or metal shavings.

Sound Analysis

Listening for rod knock using a stethoscope is a critical step in the diagnosis. Place the stethoscope on various locations around the engine block, including the cylinder head, oil pan, and valve cover. Pay attention to the rhythm and intensity of the knocking sound.

Rod knock typically produces a distinct, rhythmic tapping sound that originates from the bottom end of the engine, near the crankshaft.

Compression Test

A compression test measures the pressure within each cylinder when the piston is at its top dead center. This test can help identify if there is a loss of compression, a common symptom of rod knock. Low compression readings in a specific cylinder indicate that the connecting rod bearings may be damaged, allowing combustion gases to escape past the piston rings.

Engine Vibration

Assess engine vibrations for signs of rod knock. Excessive vibrations, particularly at high RPMs, can indicate that the connecting rod bearings are worn or damaged. Vibrations can also be felt in the steering wheel, shifter, or other parts of the vehicle.

Differentiating Rod Knock from Other Engine Noises

It’s crucial to distinguish rod knock from other engine noises that may sound similar.

Common Engine Noises

Other common engine noises that can be mistaken for rod knock include:

- Piston Slap:This noise occurs when the piston moves freely within the cylinder, creating a slapping sound. Piston slap is typically a high-pitched, metallic sound that can be heard at idle or during acceleration.

- Valve Tick:Valve tick is a clicking or tapping sound that originates from the valve train. It is typically a high-pitched sound that can be heard at idle or during acceleration.

- Main Bearing Knock:Main bearing knock is a knocking sound that originates from the crankshaft bearings. It is typically a low-pitched, rumbling sound that can be heard at idle or during acceleration.

- Connecting Rod Knock:Connecting rod knock is a knocking sound that originates from the connecting rod bearings. It is typically a high-pitched, metallic sound that can be heard at idle or during acceleration.

Distinguishing Features

The following table highlights the distinguishing features of rod knock and other common engine noises:

| Noise | Location | Sound | Characteristics |

|---|---|---|---|

| Rod Knock | Connecting rod bearings | High-pitched, metallic tapping or clicking sound | Intensifies with engine speed, rhythmic and consistent, can be heard at idle or during acceleration. |

| Piston Slap | Piston within the cylinder | High-pitched, metallic slapping sound | Typically heard at idle or during acceleration, can be a sharp or dull sound, may be accompanied by rattling or knocking. |

| Valve Tick | Valve train | High-pitched, clicking or tapping sound | Typically heard at idle or during acceleration, may be a single tick or a series of ticks, can be caused by worn valve lifters or loose rocker arms. |

| Main Bearing Knock | Crankshaft bearings | Low-pitched, rumbling or knocking sound | Typically heard at idle or during acceleration, may be a dull or sharp sound, can be caused by worn main bearings or loose crankshaft. |

Diagnostic Tools

Stethoscope

A stethoscope is an essential tool for diagnosing rod knock. It amplifies the sounds from the engine, making it easier to identify the location and characteristics of the noise. To use a stethoscope, place the earpiece in your ear and the probe on various locations around the engine block.

Listen for the rhythmic knocking sound that is characteristic of rod knock.

Compression Tester

A compression tester is a specialized tool used to measure the pressure within each cylinder. It consists of a gauge, a hose, and an adapter that fits into the spark plug hole.

Procedure

To perform a compression test, follow these steps:

- Remove the spark plugs from all cylinders.

- Connect the compression tester hose to the adapter and insert the adapter into the spark plug hole of the cylinder you are testing.

- Have an assistant crank the engine over for several seconds, while you observe the compression reading on the gauge.

- Repeat steps 2 and 3 for each cylinder.

Interpretation

Low compression readings in a specific cylinder indicate that the connecting rod bearings may be damaged, allowing combustion gases to escape past the piston rings. If all cylinders have low compression readings, it may indicate a problem with the engine’s overall condition, such as a blown head gasket or worn piston rings.

Writing a Prompt for an AI Assistant

“Write a detailed explanation of how to diagnose rod knock in an internal combustion engine. Include information on the symptoms, causes, and how to differentiate rod knock from other engine noises. Also, explain how to use diagnostic tools like a stethoscope and compression tester.”

Assessing the Severity of Rod Knock

The sound of rod knock can be a terrifying experience for any car owner. It’s a telltale sign of trouble within your engine, but the severity of the issue can vary widely. Understanding the nuances of rod knock, its progression, and its potential consequences is crucial for making informed decisions about your vehicle.

Noise Level Analysis

The sound of rod knock can provide valuable clues about its severity. A trained ear can differentiate between mild, moderate, and severe rod knock based on the sound’s pitch, rhythm, and intensity.

| Severity Level | Noise Pitch | Noise Rhythm | Noise Intensity |

|---|---|---|---|

| Mild | High | Consistent | Faint |

| Moderate | Medium | Irregular | Moderate |

| Severe | Low | Intermittent | Loud |

Engine Performance Evaluation

Rod knock can also manifest in noticeable changes to your engine’s performance. These symptoms can range from subtle to alarming, depending on the severity of the rod knock.

| Severity Level | Engine Performance Symptom | Description |

|---|---|---|

| Mild | Loss of Power | You may notice a slight decrease in acceleration or a feeling of sluggishness. |

| Moderate | Rough Idling | The engine may shake or vibrate noticeably at idle, and the RPM may fluctuate. |

| Severe | Excessive Vibration | The engine may shake violently, even at higher RPMs, and you may feel vibrations throughout the vehicle. |

| Severe | Smoke from Exhaust | Blue or white smoke from the exhaust indicates oil burning, which can be a sign of severe rod knock. |

Potential Consequences of Ignoring Rod Knock

Ignoring rod knock can lead to serious consequences, including significant engine damage and even catastrophic engine failure.

Ignoring rod knock is like ignoring a nagging cough – it might seem like a minor issue at first, but it can quickly escalate into a major problem.

Engine Damage

As rod knock progresses, the connecting rod and crankshaft bearings wear down, leading to increased friction and heat. This can damage the crankshaft, connecting rod, and other engine components.

Catastrophic Failure

If rod knock is left untreated, the connecting rod can eventually break, causing the piston to detach from the crankshaft. This can lead to a catastrophic engine failure, requiring a complete engine rebuild or replacement.

Safety Risks

Driving a vehicle with severe rod knock can be dangerous. The engine may lose power suddenly, leading to loss of control, or it could seize up completely, leaving you stranded. In extreme cases, a catastrophic engine failure can lead to an engine fire.

Factors Influencing Severity

Several factors can influence the severity of rod knock, including engine size, load, and driving conditions.

| Factor | Impact | Example |

|---|---|---|

| Engine Size | Larger engines generally have more robust components and can tolerate rod knock for longer. | A V8 engine with rod knock may be able to run for a longer period than a 4-cylinder engine with the same issue. |

| Engine Load | Heavy loads, such as towing or hauling, can exacerbate rod knock and accelerate engine damage. | Towing a trailer with a vehicle that has rod knock can cause the problem to worsen quickly. |

| Driving Conditions | Driving in extreme conditions, such as high temperatures or dusty environments, can increase wear and tear on engine components, including bearings. | Driving in desert environments can cause the engine to overheat, which can worsen rod knock. |

Repair Options for Rod Knock

Rod knock is a serious engine problem that can lead to catastrophic engine failure if left untreated. While it may seem daunting, you have a few options when it comes to repairing rod knock. The best approach depends on the severity of the knock, your budget, and your desired engine performance.

Engine Rebuild

An engine rebuild is the most comprehensive repair option for rod knock. This involves disassembling the engine, inspecting all components, replacing worn or damaged parts, and reassembling the engine. A rebuild can restore your engine to factory specifications or even improve its performance.

- Benefits:An engine rebuild is the most thorough repair option, ensuring your engine is restored to its best possible condition. It can also be a good opportunity to upgrade your engine with high-performance parts.

- Drawbacks:Engine rebuilds are time-consuming and expensive. It can take several days or weeks to complete, and the cost can range from a few thousand dollars to tens of thousands, depending on the complexity of the rebuild and the parts used.

Engine Replacement

If the rod knock is severe or the engine has significant wear, an engine replacement may be the most practical option. This involves replacing the entire engine with a new or used engine.

- Benefits:An engine replacement is a relatively quick and straightforward repair. It can be completed in a few days, and the cost is often less than a rebuild, especially if you use a used engine.

- Drawbacks:An engine replacement may not be as reliable as a rebuild, especially if you use a used engine. You may also encounter compatibility issues if the replacement engine is not the same as the original.

Potential Fixes for Minor Cases

In some cases, rod knock may be caused by a minor issue, such as a loose connecting rod bolt or a worn piston pin. If the knock is minor and the engine is still running, you may be able to fix it without a major repair.

- Benefits:These fixes are relatively inexpensive and can be completed quickly.

- Drawbacks:These fixes are not always successful, and they may only be a temporary solution. If the rod knock is severe, these fixes will not be effective.

Prevention of Rod Knock

Rod knock, that dreaded metallic knocking sound in your engine, is a nightmare for any car owner. But don’t worry, you can prevent this problem by following some simple tips. It’s all about being proactive and taking good care of your engine.

Regular Oil Changes

Regular oil changes are crucial for preventing rod knock. Oil lubricates the moving parts of your engine, reducing friction and wear. Over time, oil breaks down and loses its ability to lubricate effectively. This can lead to increased wear on the connecting rod bearings, ultimately causing rod knock.

- Follow your car manufacturer’s recommended oil change intervals. This information is usually found in your owner’s manual.

- Consider using synthetic oil, which has a longer lifespan and better high-temperature performance than conventional oil.

- If you drive in harsh conditions, such as extreme heat or frequent stop-and-go traffic, you may need to change your oil more often.

Using High-Quality Oil

Just like choosing the right surfboard for the perfect wave, choosing the right oil for your engine is essential. Using high-quality oil helps ensure your engine runs smoothly and efficiently.

Using the Correct Type of Oil and Oil Filter

The type of oil you use is crucial for protecting your engine. Consult your owner’s manual for the recommended oil viscosity and type for your vehicle. Using the wrong oil can lead to increased wear and tear on engine components, including the connecting rod bearings.

- Using a higher viscosity oil than recommended can cause excessive friction and heat, increasing the risk of rod knock.

- Using a lower viscosity oil than recommended can lead to insufficient lubrication, also increasing the risk of rod knock.

Maintaining Proper Engine Temperature

Just like you wouldn’t want to spend too much time in a sauna or a freezer, your engine also needs a comfortable operating temperature. Excessive heat can lead to oil breakdown and premature wear on engine components.

- Ensure your cooling system is functioning properly. This includes checking the coolant level, radiator cap, and thermostat.

- Avoid driving your car hard immediately after starting it. Allow the engine to warm up properly before accelerating heavily.

Avoiding Driving Habits that Contribute to Rod Knock

Think of your engine like a surfer catching a big wave; it needs to be handled with care. Aggressive driving habits, such as hard acceleration and heavy towing, can put excessive stress on your engine, increasing the risk of rod knock.

- Avoid revving the engine too high, especially when the engine is cold.

- Avoid sudden stops and starts.

- If you need to tow heavy loads, consider using a lower gear to reduce stress on the engine.

Engine Components Affected by Rod Knock

Rod knock, a telltale sign of a failing connecting rod bearing, can wreak havoc on your engine’s internal components. It’s not just a knocking sound; it’s a symptom of a serious problem that can lead to catastrophic engine failure if left unaddressed.

Understanding which parts are most vulnerable to damage from rod knock is crucial for making informed decisions about repairs and prevention.

Engine Components Susceptible to Rod Knock Damage

Rod knock directly affects the connecting rod, bearings, and crankshaft. These components work in unison to transfer power from the piston to the crankshaft, and damage to any of these parts can disrupt this crucial process.

| Component | Damage Caused by Rod Knock |

|---|---|

| Connecting Rod |

|

| Bearings |

|

| Crankshaft |

|

Consequences of Rod Knock on Other Engine Systems

Rod knock doesn’t just affect the immediate components. Its damaging effects can spread throughout the engine, impacting other vital systems:

- Oil System:The oil system is crucial for lubrication and cooling. Rod knock can cause metal debris from the damaged bearings to circulate in the oil, leading to further wear and tear on other engine components, including the oil pump and filter.

This can also lead to oil starvation, which can further exacerbate the damage.

- Cooling System:Rod knock can also affect the cooling system. If the engine overheats due to oil starvation or debris clogging the cooling system, it can lead to further damage to the engine, including warping of the cylinder head and piston damage.

Impact of Rod Knock on Other Engine Components

Rod knock can lead to damage to other engine components, such as the piston and cylinder wall. The piston, which is directly connected to the connecting rod, can be damaged by the excessive force and vibration caused by rod knock.

This can lead to piston ring failure, piston scuffing, and even piston seizure. The cylinder wall, which houses the piston, can also be damaged by the excessive force and vibration, resulting in scoring or even cracks.

Rod knock is a serious issue that requires immediate attention. Ignoring the problem can lead to further damage and ultimately, a costly engine rebuild or replacement.

7. Rod Knock vs. Other Engine Noises

Engine noises can be a source of anxiety for any car owner. While rod knock is a serious issue, it’s important to differentiate it from other common engine noises to avoid unnecessary panic and ensure the right diagnosis. This section will help you understand the unique sounds of rod knock and compare it to other engine noises, guiding you towards an accurate diagnosis.

Sound Comparison

Understanding the distinct characteristics of different engine noises is crucial for accurate diagnosis. Here, we’ll compare the sounds of rod knock, piston slap, valve clatter, and timing chain rattle, highlighting their key differences.

- Rod Knock:Rod knock is a distinct, loud knocking sound that intensifies with engine speed. It’s often described as a “metallic clanging” or “hammering” noise that emanates from the bottom end of the engine. It’s a rhythmic sound that follows the engine’s rotation.

- Piston Slap:Piston slap is a high-pitched, rattling sound that occurs when the piston moves loosely in the cylinder. It’s usually more noticeable during cold starts and can fade away as the engine warms up.

- Valve Clatter:Valve clatter is a sharp, metallic clicking sound that occurs when the valves are not closing properly. It’s often heard at high engine speeds and can be accompanied by a loss of power.

- Timing Chain Rattle:Timing chain rattle is a distinct, metallic clicking sound that originates from the timing chain. It’s usually a constant noise that doesn’t change with engine speed.

Table of Characteristics

To further differentiate these noises, here’s a table summarizing their key characteristics:

| Sound | Location (Engine Compartment) | Potential Causes |

|---|---|---|

| Rod Knock | Bottom End of Engine | Worn or damaged connecting rod bearings, crankshaft damage, loose connecting rod bolts |

| Piston Slap | Cylinder Block | Loose piston fit, worn cylinder walls, insufficient lubrication |

| Valve Clatter | Cylinder Head | Worn valve lifters, faulty valve springs, sticking valves |

| Timing Chain Rattle | Timing Chain Cover | Worn timing chain, loose timing chain tensioner, stretched timing chain |

Troubleshooting Significance

Misdiagnosing the source of engine noise can lead to unnecessary repairs and potentially worsen the problem. An accurate diagnosis is crucial for determining the appropriate repair strategy and preventing further damage.

- Impact of Misdiagnosis:Misidentifying rod knock as another engine noise can lead to delaying essential repairs, allowing the damage to worsen and potentially causing catastrophic engine failure.

- Effective Diagnosis:Accurate diagnosis requires careful listening, observation, and potentially the use of diagnostic tools.

- Diagnostic Tools:A mechanic’s stethoscope can be used to pinpoint the location of the noise within the engine compartment. This tool can help isolate the source of the sound and provide valuable information for diagnosis.

8. Rod Knock in Different Engine Types

Rod knock, that unmistakable metallic knocking sound, can be a sign of serious trouble in your engine. Understanding how rod knock manifests in different engine types is crucial for accurate diagnosis and effective repair.

Gasoline Engines

Rod knock in gasoline engines is typically characterized by a sharp, rhythmic knocking sound that increases in intensity with engine speed. This sound is often described as a “pinging” or “clattering” noise. The severity of rod knock in gasoline engines is influenced by several factors:

- Engine Speed:Rod knock intensifies as engine speed increases, as the connecting rod bearings experience greater stress and impact.

- Engine Load:The sound of rod knock may become more pronounced under heavy load, as the crankshaft and connecting rods are subjected to increased forces.

- Engine Temperature:Rod knock can be more noticeable when the engine is cold, as the oil viscosity is higher, leading to increased friction between the connecting rod bearings and the crankshaft.

Common causes of rod knock in gasoline engines include:

- Worn Connecting Rod Bearings:Over time, the connecting rod bearings can wear down, creating excessive clearance between the bearings and the crankshaft journals. This clearance allows the connecting rod to strike the crankshaft, producing the characteristic knocking sound.

- Connecting Rod Failure:A broken or damaged connecting rod can also lead to rod knock. This failure can occur due to excessive wear, fatigue, or improper installation.

- Piston Damage:Damage to the piston, such as a cracked piston skirt or a broken piston ring, can cause the piston to move erratically within the cylinder, resulting in rod knock.

Examples of gasoline engine models known for experiencing rod knock issues include:

- Honda B-series Engines:These engines, commonly found in Honda Civics and Accords, are known for their high-revving capabilities but have been susceptible to rod knock, particularly when subjected to high performance modifications.

- Ford 5.4L Triton V8:This engine, used in various Ford trucks and SUVs, has been plagued by rod knock issues, often attributed to faulty connecting rod bearings.

Diesel Engines

Rod knock in diesel engines can sound similar to gasoline engines, but it often has a deeper, more pronounced “clunking” or “thumping” quality due to the higher compression ratios and heavier loads experienced in diesel engines.

- High Compression Ratios:Diesel engines operate at much higher compression ratios than gasoline engines, which places greater stress on the connecting rod bearings. This increased stress can contribute to premature wear and rod knock.

- Heavy-Duty Applications:Diesel engines are commonly used in heavy-duty applications, such as trucks and construction equipment, where they are subjected to high torque and prolonged operation under heavy loads. These demanding conditions can accelerate wear on the connecting rod bearings and increase the likelihood of rod knock.

Lubrication and fuel quality play a critical role in preventing rod knock in diesel engines:

- Lubrication:Proper lubrication is essential for minimizing friction and wear on the connecting rod bearings. Using the correct viscosity and type of oil, as recommended by the manufacturer, is crucial.

- Fuel Quality:Low-quality diesel fuel can contain contaminants that can damage engine components, including the connecting rod bearings. Using clean, high-quality fuel is important for preventing rod knock.

Examples of diesel engine models that are prone to rod knock include:

- Cummins ISX:This engine, used in heavy-duty trucks, has been known to experience rod knock issues, often related to improper maintenance practices or inadequate lubrication.

- Caterpillar 3406E:This engine, used in heavy-duty construction equipment, has also been reported to experience rod knock, particularly when subjected to extreme operating conditions.

Rotary Engines

Rotary engines, with their unique design, present a different set of challenges when it comes to rod knock. These engines feature an eccentric rotor that rotates within a housing, and the apex seals, which are responsible for sealing the combustion chamber, play a crucial role in preventing rod knock.

- Eccentric Rotor:The eccentric rotor’s motion generates significant forces on the connecting rod bearings, making them susceptible to wear and damage.

- Apex Seals:Worn or damaged apex seals can lead to combustion gas leakage into the crankcase, which can contaminate the oil and contribute to rod knock.

Diagnosing and addressing rod knock in rotary engines can be more challenging due to the unique design and operating principles.

- Diagnosis:The sound of rod knock in rotary engines can be more difficult to distinguish from other engine noises, making diagnosis more complex.

- Repair:Replacing connecting rod bearings or the rotor in a rotary engine requires specialized tools and expertise.

Examples of rotary engine models that have experienced rod knock issues include:

- Mazda RX-7:This iconic sports car, powered by a rotary engine, has been known to experience rod knock, particularly in high-performance models.

- Mazda RX-8:The RX-8, also powered by a rotary engine, has also been reported to experience rod knock, often attributed to improper maintenance or high-performance modifications.

Cost of Repairing Rod Knock

Fixing rod knock can be a serious financial undertaking, especially if you’re dealing with a complex engine or a severe case of rod knock. It’s important to understand the costs involved and explore all your options to make an informed decision.

Cost Breakdown

The cost of repairing rod knock can vary significantly depending on several factors. Here’s a breakdown of the major cost components:

- Engine Type:More complex engines, like those found in luxury vehicles or high-performance cars, will generally cost more to repair.

- Labor Costs:The cost of labor can vary depending on your location and the mechanic’s expertise. Shop around for quotes and consider independent mechanics for potentially lower labor costs.

- Parts Availability:If you need to replace parts, their availability and cost can influence the overall repair bill. Salvaged parts can be a more affordable option, but it’s crucial to ensure their quality.

- Severity of Rod Knock:The extent of the damage will determine the complexity of the repair. Minor cases may only require replacing a rod bearing, while more severe cases may require a complete engine rebuild or even replacement.

Potential Hidden Costs

It’s important to be aware of potential hidden costs associated with rod knock repair. These can include:

- Engine Removal and Installation:In many cases, the engine needs to be removed from the vehicle for repair. This involves labor costs for removal, installation, and any associated adjustments.

- Additional Repairs:Rod knock can sometimes indicate other underlying problems within the engine. You may need to address these issues during the repair process, adding to the overall cost.

Finding Affordable Repair Options

Here are some tips for finding more affordable repair options for rod knock:

- Shop Around:Get quotes from multiple mechanics, including independent shops and dealerships.

- Consider Salvaged Parts:Salvaged parts can be a cost-effective alternative to new parts, but ensure their quality and compatibility with your engine.

- DIY Repair:If you have mechanical skills, consider doing some of the work yourself. However, this can be complex and risky, so only attempt it if you’re confident in your abilities.

Impact of Rod Knock on Vehicle Performance

Rod knock, a telltale sign of a failing engine, doesn’t just make an unpleasant noise; it significantly impacts your vehicle’s performance, potentially leading to catastrophic engine failure. This section delves into the ways rod knock affects your car’s power, fuel consumption, and overall drivability.

Engine Movement and Sound

Rod knock arises from a worn or damaged connecting rod bearing, causing the piston and connecting rod assembly to move abnormally within the cylinder. This irregular movement produces a distinctive knocking sound that intensifies with engine speed. Imagine a loose bolt rattling around inside a metal container – that’s the sound of rod knock, but amplified within your engine.

The knocking sound is often described as a “metallic clunking” or “tapping” noise, and it typically gets louder as the engine warms up.

Power Reduction

Rod knock significantly reduces engine power. The damaged bearing allows the connecting rod to move excessively, hindering the piston’s ability to transfer power to the crankshaft. This results in a noticeable loss of acceleration, making your car feel sluggish and unresponsive.

The reduction in power can be substantial, depending on the severity of the rod knock.

Increased Fuel Consumption

Rod knock also leads to increased fuel consumption. The irregular movement of the piston and connecting rod disrupts the combustion process, resulting in incomplete burning of fuel. This means your engine is burning more fuel to produce the same amount of power, leading to poorer fuel economy.

Engine Misfire

Rod knock can also cause engine misfires. The abnormal movement of the piston and connecting rod can disrupt the timing of the spark plug firing, resulting in misfires. Misfires are characterized by a rough idle, hesitation during acceleration, and a decrease in power.

Progressive Damage

Rod knock is not a static condition; it progressively worsens over time. The damaged bearing continues to wear, increasing the severity of the knocking sound and further impacting performance. Eventually, the bearing may fail completely, leading to catastrophic engine damage.

Crankshaft Damage

As rod knock progresses, the damaged bearing can cause damage to the crankshaft. The excessive movement of the connecting rod can wear down the crankshaft journals, leading to a loss of lubrication and further damage. This can eventually lead to bearing failure, requiring a complete engine rebuild or replacement.

Catastrophic Engine Failure

The risk of catastrophic engine failure is directly related to the severity of rod knock. In severe cases, the connecting rod can break, causing the piston to detach from the crankshaft and damage other engine components. This can lead to a complete engine seizure, requiring a costly engine replacement.

Real-World Examples

Rod knock is a common problem in older vehicles, particularly those with high mileage. For instance, a 2005 Honda Civic with 150,000 miles might experience rod knock due to worn connecting rod bearings. The owner might notice a loss of power, increased fuel consumption, and a knocking sound from the engine.

Repairing the rod knock in this case could cost several thousand dollars, depending on the extent of the damage.

Forum Insights

Automotive forums are filled with discussions about rod knock. Many owners describe the distinctive knocking sound, the loss of power, and the increased fuel consumption. Some forums even provide detailed accounts of catastrophic engine failures caused by rod knock.

Rod Knock in Different Vehicle Makes and Models: How To Fix Rod Knock

While rod knock can occur in any engine, certain vehicle makes and models are more prone to developing this issue. This susceptibility is often linked to specific engine designs, manufacturing defects, or common maintenance practices. Understanding these patterns can help you identify potential risks and take preventative measures.

Common Vehicle Makes and Models Susceptible to Rod Knock

This section explores some vehicle makes and models known to be susceptible to rod knock. It’s important to note that these are general observations, and individual cases may vary.

- Honda Civic (1992-2000):The D16 series engines in these models are known for experiencing rod knock, particularly when the engine oil is not changed regularly or if the oil filter is clogged. The high-revving nature of these engines can also contribute to wear and tear on the connecting rods.

- Ford Focus (2000-2007):The 2.0L Zetec engine in these models is notorious for rod knock, especially in the early production years. This is often attributed to inadequate lubrication, leading to premature wear on the connecting rods.

- Chevrolet Cobalt (2005-2010):The 2.2L Ecotec engine in these models has been linked to rod knock issues, primarily due to a faulty oil pump design. The oil pump can fail to deliver adequate lubrication, causing excessive wear on the connecting rods.

- Toyota Camry (2007-2011):Some models with the 2.4L 2AZ-FE engine have reported rod knock issues. While not as widespread as in other vehicles, it is a concern, potentially related to insufficient lubrication or faulty connecting rod bearings.

Legal and Ethical Considerations of Rod Knock

Selling a vehicle with a known rod knock presents a complex web of legal and ethical considerations. It’s crucial to understand the potential ramifications, both legal and ethical, before making any decisions about selling or buying such a vehicle.

Legal Obligations

Laws regarding the disclosure of vehicle defects vary by jurisdiction. Some areas require sellers to disclose any known defects, while others have more lenient regulations. It’s essential to consult with local authorities or legal professionals to understand the specific requirements in your region.

Failing to disclose a known defect could lead to legal action from the buyer, potentially resulting in financial penalties, lawsuits, and damage to your reputation.

Ethical Implications

Selling a vehicle with rod knock without disclosing the issue raises significant ethical concerns. It’s a serious mechanical problem that can lead to catastrophic engine failure and pose safety risks. Transparency is crucial when selling a vehicle, and withholding information about a major defect like rod knock can be considered dishonest and potentially harmful.

Consumer Protection Laws

Consumer protection laws are designed to safeguard buyers from unfair or deceptive practices. These laws often require sellers to disclose any known defects that could significantly impact the vehicle’s value or safety. Failure to comply with these laws could result in legal action and penalties.

It’s essential to understand the specific consumer protection laws in your jurisdiction and ensure you comply with them.

Potential Risks and Liabilities

Driving a vehicle with rod knock poses significant risks, both to the driver and others on the road.

Safety Hazards

The damaged connecting rod can break, leading to catastrophic engine failure. This can cause the engine to seize, potentially leading to loss of power, control, and even a collision. The severity of the damage depends on the severity of the rod knock.

Financial Risks

Driving a vehicle with rod knock increases the risk of an accident. This could result in significant financial losses, including repair costs, medical expenses, and potential legal claims.

Liability in Case of an Accident

If an accident occurs due to a vehicle with rod knock, the driver could be held liable for damages and injuries. The severity of the liability depends on the specific circumstances of the accident and the jurisdiction. Failing to disclose the rod knock issue to potential buyers could also expose the seller to further liability.

Disclosing Rod Knock to Potential Buyers

Transparency is key when selling a vehicle with rod knock. It’s crucial to be upfront and honest with potential buyers about the issue.

Methods of Disclosure

The most effective ways to disclose rod knock include:

- Clearly stating the issue in the vehicle description, both online and in any written documentation.

- Providing detailed information about the severity of the rod knock and the potential consequences.

- Allowing potential buyers to have the vehicle inspected by a qualified mechanic.

- Demonstrating the rod knock sound to the potential buyer.

Documentation

Provide documentation to potential buyers that clearly Artikels the rod knock issue. This documentation could include:

- A detailed description of the problem, including the date it was discovered and the extent of the damage.

- Repair estimates from reputable mechanics.

- Any relevant repair history related to the engine.

Negotiation

Be prepared to negotiate a fair price with the potential buyer. The price should reflect the vehicle’s condition and the potential repair costs associated with the rod knock.

Real-Life Cases and Scenarios

There have been numerous legal cases involving the sale of vehicles with undisclosed mechanical issues, including rod knock. In some instances, buyers have successfully sued sellers for failing to disclose known defects. These cases highlight the importance of transparency and the potential legal consequences of concealing information about a vehicle’s condition.

The Importance of Professional Diagnosis and Repair for Rod Knock

Rod knock is a serious engine problem that can quickly escalate into a major issue if not addressed promptly. It’s like a warning sign that your engine is in trouble, and ignoring it could lead to a costly and inconvenient breakdown.

This is why seeking professional diagnosis and repair is crucial for dealing with rod knock.

Why Professional Diagnosis and Repair Are Essential

Rod knock is a complex issue that requires specialized knowledge and tools to diagnose and repair correctly. Trying to fix it yourself without proper training and equipment can lead to further damage to your engine and potentially dangerous situations.

- Specialized Knowledge and Tools:Diagnosing and repairing rod knock involves a deep understanding of engine mechanics, as well as the use of specialized tools and equipment. Mechanics have the expertise and resources to accurately pinpoint the problem and perform the necessary repairs.

- Potential for Further Damage:Attempting DIY repairs without the right knowledge and tools can lead to further damage to your engine, resulting in increased repair costs and potential engine failure. You could end up spending more in the long run trying to fix a problem you made worse.

- Safety Risks:Working on a car engine can be dangerous, especially if you’re not familiar with the proper procedures and safety precautions. Attempting to fix rod knock yourself could lead to personal injury, such as burns from hot engine components or cuts from sharp tools.

Examples of Potential Consequences of DIY Repairs

Let’s say you decide to tackle the rod knock yourself and try to replace the connecting rod bearings. Without proper experience, you might misalign the bearings or overtighten the bolts, causing further damage to the crankshaft and other engine components.

This could lead to engine failure, requiring a complete engine rebuild or even a replacement.Think about the potential costs involved: towing fees, engine repair costs, and lost wages due to being unable to use your vehicle. The financial burden of attempting DIY repairs that go wrong can be significant.

Rod knock is a serious engine problem that should not be attempted to be repaired by anyone without proper knowledge and tools. Attempting to repair rod knock without proper training can lead to further damage to the engine and potentially serious injury.

Future Developments and Research in Rod Knock Prevention

The battle against rod knock is a constant evolution in the automotive world. Engineers and researchers are always on the lookout for new ways to prevent this engine-killing issue. From advancements in engine design to the use of cutting-edge materials, the quest for rod knock-free engines continues.

Engine Design Innovations

Engine design plays a crucial role in preventing rod knock. The latest innovations focus on reducing stress on the connecting rods and bearings. Here are some examples:

- Optimized Connecting Rod Design:Manufacturers are using computer simulations and advanced analysis to optimize the shape and material of connecting rods. This helps to distribute stress more evenly, reducing the likelihood of failure.

- Improved Bearing Materials:New materials like ceramic coatings and advanced metal alloys are being developed for engine bearings. These materials offer superior wear resistance and heat dissipation, reducing the risk of bearing failure.

- Variable Valve Timing (VVT):VVT systems allow for more precise control over engine timing, which helps to optimize combustion and reduce the load on the connecting rods.

- Direct Injection Systems:Direct injection systems deliver fuel directly into the combustion chamber, improving fuel efficiency and reducing engine knock.

Advanced Materials for Engine Components

Material science plays a vital role in preventing rod knock. Researchers are continuously developing new materials that offer improved strength, durability, and resistance to wear and tear.

- Nanomaterials:Nanomaterials are being explored for their potential to enhance the strength and durability of engine components. For example, nano-sized ceramic particles can be incorporated into bearing materials to improve wear resistance.

- Lightweight Alloys:Lightweight alloys, like aluminum and magnesium, are being used to reduce the weight of engine components, which helps to reduce stress on the connecting rods and bearings.

- Composite Materials:Composite materials, which combine different materials like carbon fiber and polymers, are being investigated for their potential to improve the strength and durability of engine components.

Historical Perspective on Rod Knock

Rod knock, a telltale sign of engine trouble, has a history as long as the internal combustion engine itself. Understanding its origins and evolution sheds light on how engine technology has advanced to mitigate this problem.

Origins and Evolution of Rod Knock

Rod knock, a rhythmic knocking sound emanating from the engine, is a result of wear and tear on the connecting rod bearings, which connect the piston to the crankshaft. These bearings are designed to allow smooth, controlled movement, but over time, they can wear down, leading to excessive clearance and a knocking sound.

The origins of rod knock can be traced back to the early days of the internal combustion engine. Early engines were prone to this issue due to their relatively simple design and lack of sophisticated lubrication systems. As engine technology progressed, advancements in materials, manufacturing processes, and lubrication systems led to a significant reduction in the prevalence and severity of rod knock.

Impact of Engine Technology Advancements

Advancements in engine technology have played a significant role in reducing the frequency and severity of rod knock.

- The development of stronger and more durable materials for connecting rod bearings, such as babbitt, bronze, and more recently, tri-metal bearings, has increased their resistance to wear and tear.

- Improved engine lubrication systems, with better oil pumps, filters, and oil formulations, provide more effective lubrication and protection for the bearings.

- Advances in manufacturing techniques have led to more precise and consistent bearing clearances, reducing the risk of excessive wear.

Notable Examples of Rod Knock in Historical Vehicles

Rod knock has played a significant role in the history of automobiles, and its impact can be seen in various examples:

- The Model T Ford, known for its durability, was not immune to rod knock. The engine’s relatively simple design and lack of sophisticated lubrication systems made it prone to this issue, particularly in later models.

- The Volkswagen Beetle, another iconic vehicle, was notorious for its engine’s susceptibility to rod knock, especially in older models. This was due to a combination of factors, including the engine’s design, the use of low-quality oil, and the lack of proper maintenance.

- In the early days of motorsport, rod knock was a common problem, often leading to engine failures and race retirements. This spurred innovation in engine design and lubrication systems, ultimately leading to more reliable and powerful engines.

Detailed FAQs

What are the common causes of rod knock?

Worn bearings, lack of lubrication, engine overheating, and improper installation are common culprits.

How much does it cost to fix rod knock?

The cost can vary widely depending on the severity of the damage and the repair method. It can range from a few hundred dollars for a minor repair to thousands for a full engine rebuild.

Can I drive my car with rod knock?

It’s not advisable to drive a car with rod knock, as it can cause further damage and potentially lead to a catastrophic engine failure.

What are the signs of rod knock?

The most common sign is a knocking sound that gets louder with engine speed. You may also notice a loss of power, increased oil consumption, or engine vibration.

Is rod knock repairable?

In some cases, rod knock can be repaired by replacing the damaged bearings. However, if the damage is extensive, a full engine rebuild or replacement may be necessary.