How to fix mechanical watch lagging behind is a question that plagues many watch enthusiasts. It’s a frustrating experience when your cherished timepiece starts running slow, leaving you feeling like you’re always behind schedule. The intricate world of mechanical watches, with their delicate movements and intricate components, can be a source of both admiration and anxiety.

But don’t despair! Understanding the reasons behind a lagging watch and knowing how to troubleshoot and prevent this issue can bring your timepiece back to life and ensure its accuracy for years to come.

This guide will delve into the common causes of a lagging mechanical watch, providing a step-by-step approach to diagnosing the problem. We’ll explore the different types of mechanical movements, discuss the role of proper winding and maintenance, and offer practical tips for preventing future lagging issues.

From understanding the intricate workings of your watch to learning how to adjust its timing, we’ll empower you to become a more informed and confident watch owner.

Understanding Mechanical Watch Lagging

A mechanical watch lagging behind, also known as running slow, is a common issue that can be frustrating for watch enthusiasts. Understanding the reasons behind this phenomenon is crucial for effectively troubleshooting and preventing it.

Common Causes of a Mechanical Watch Running Slow

Several factors can contribute to a mechanical watch running slow.

- Insufficient Winding:A mechanical watch requires regular winding to maintain its power reserve. If the watch is not wound sufficiently, the mainspring will not have enough energy to power the movement, leading to a slower pace.

- Friction:Friction within the watch’s movement, caused by worn or dirty components, can impede the smooth operation of the gears and other moving parts, resulting in a slower timekeeping.

- Wear and Tear:Over time, the watch’s components, such as gears, bearings, and springs, can wear down due to constant use. This wear can lead to increased friction and reduced efficiency, ultimately causing the watch to run slow.

- Balance Wheel Issues:The balance wheel is a critical component responsible for regulating the watch’s rhythm. If the balance wheel is not functioning correctly, due to wear or misalignment, it can affect the watch’s timekeeping accuracy.

- Temperature Fluctuations:Extreme temperatures can affect the watch’s movement, causing it to run slow or fast. For example, cold temperatures can make the oil in the movement thicker, increasing friction and slowing down the watch.

- Magnetic Fields:Exposure to strong magnetic fields can interfere with the watch’s movement, causing it to run slow or fast.

- Shock:A sudden impact or shock can damage the watch’s movement, leading to a variety of problems, including running slow.

Types of Mechanical Watch Movements

Mechanical watches are broadly classified into two main types of movements: manual-winding and automatic.

Manual-Winding Movements

Manual-winding movements rely solely on the user to wind the mainspring. The user must manually turn the crown to wind the watch and provide energy for the movement.

Automatic Movements

Automatic movements use a rotor to wind the mainspring as the wearer moves their wrist. The rotor is a weighted component that spins as the wrist moves, generating energy to wind the mainspring.

Factors Contributing to a Watch Running Slow, How to fix mechanical watch lagging behind

- Friction:Friction is a major factor that can cause a watch to run slow. Friction occurs when two surfaces rub against each other, creating resistance to movement. In a mechanical watch, friction can occur between the gears, bearings, and other moving parts.

The amount of friction can be influenced by the quality of the materials used, the lubrication, and the wear and tear on the components.

- Wear and Tear:Over time, the components of a mechanical watch can wear down due to constant use. This wear can lead to increased friction, reduced efficiency, and ultimately, a slower timekeeping. Worn gears, bearings, and springs can all contribute to a lagging watch.

- Improper Winding:Winding a watch incorrectly can also contribute to it running slow. If the mainspring is not fully wound, it will not have enough energy to power the movement for the full duration. Overwinding the mainspring can also damage it, leading to a loss of power and a slower timekeeping.

Diagnosing the Problem

Once you’ve determined that your mechanical watch is lagging behind, the next step is to diagnose the root cause. This involves carefully observing the watch’s behavior and identifying any unusual patterns or noises that could indicate a specific problem.

Identifying Potential Causes

Understanding the nature of the lagging can help narrow down the potential causes.

- Consistent Slowness:If the watch consistently loses time at a steady rate, it might indicate a general power reserve issue, a worn-out mainspring, or a problem with the escapement mechanism.

- Intermittent Slowness:Fluctuations in the watch’s accuracy, with periods of normal timekeeping followed by periods of lagging, could suggest issues with the balance wheel, hairspring, or even dust or debris affecting the movement.

- Sudden Changes in Timekeeping:If the watch suddenly starts losing time significantly, it could point to a more serious issue like a broken part, a detached component, or a sudden change in the watch’s environment, such as a strong magnetic field.

Observing the Watch’s Movement

Closely observing the watch’s movement can provide valuable insights.

- Balance Wheel Oscillations:The balance wheel should oscillate smoothly and consistently. Irregular or uneven oscillations can indicate a problem with the hairspring, balance wheel bearings, or the escapement mechanism.

- Ticking Sound:The ticking sound should be clear and consistent. A muffled or irregular ticking sound could indicate a problem with the escapement, gears, or even a loose part.

- Power Reserve:Pay attention to the watch’s power reserve. If it runs out of power prematurely, it might indicate a weak mainspring or a problem with the winding mechanism.

Watchmaker’s Expertise

While you can perform some basic observations, diagnosing complex issues requires the expertise of a qualified watchmaker. A watchmaker has the specialized tools, knowledge, and experience to:

- Examine the Movement:They can carefully inspect the watch’s internal components for any signs of wear, damage, or misalignment.

- Test the Timekeeping Accuracy:They can use precision timing equipment to accurately assess the watch’s timekeeping performance and identify any deviations.

- Identify the Root Cause:Based on their observations and tests, they can pinpoint the specific cause of the lagging and recommend appropriate repairs.

3. Basic Troubleshooting Steps

Troubleshooting a mechanical watch that is lagging behind involves a series of steps to identify the source of the problem. By systematically checking the watch’s functionality, you can often pinpoint the issue and take appropriate action.

3.1. Adjusting Time on a Mechanical Watch

Adjusting the time on a mechanical watch is a fundamental skill that every owner should master. The process varies slightly depending on whether the watch has a hand-wound or automatic movement.

Hand-Wound Movement

- Pull the crown out to the first position. This disengages the crown from the movement, allowing you to adjust the time.

- Turn the crown clockwise to advance the hour and minute hands. The crown should turn smoothly, and you should feel a slight resistance as the hands move.

- Push the crown back in to the normal position. This re-engages the crown with the movement and locks the time setting.

Automatic Movement

- Pull the crown out to the second position. This disengages the crown from the movement and allows you to adjust the time.

- Turn the crown clockwise to advance the hour hand. The hour hand will move independently of the minute hand.

- Turn the crown counterclockwise to advance the minute hand. The minute hand will move independently of the hour hand.

- Push the crown back in to the normal position. This re-engages the crown with the movement and locks the time setting.

3.2. Checking and Adjusting Winding Mechanism

The winding mechanism is the heart of a mechanical watch, responsible for powering the movement. Checking and adjusting the winding mechanism is crucial for ensuring proper operation and maximizing power reserve.

Hand-Winding

- Pull the crown out to the first position. This disengages the crown from the movement, allowing you to wind the watch.

- Turn the crown clockwise until it feels resistance. This indicates that the mainspring is fully wound. Overwinding can damage the movement, so it’s essential to stop winding when you feel resistance.

- Push the crown back in to the normal position. This re-engages the crown with the movement and locks the winding mechanism.

Automatic Winding

- Observe the watch while wearing it to ensure the rotor is moving freely. The rotor is a weighted component that spins as you move your wrist, winding the mainspring.

- If the rotor is not moving, try shaking the watch gently to activate it. This should initiate the winding process.

- If the watch is not winding properly, consult a watchmaker. A malfunctioning rotor or other winding mechanism issues may require professional attention.

3.3. Role of a Watch Winder and Its Impact on Timing Accuracy

A watch winder is a device designed to maintain the power reserve of a mechanical watch by simulating the movement of the wearer’s wrist. While a watch winder can be beneficial in keeping the watch running, its use can also have an impact on timing accuracy.

Role of a Watch Winder

- Purpose: To keep the watch wound and running even when not being worn.

- Function: Simulates the movement of the wearer’s wrist to activate the automatic winding mechanism.

Impact on Accuracy

- Potential Benefits: Consistent winding can improve accuracy by preventing the watch from stopping due to low power reserve.

- Potential Drawbacks: Excessive winding can put stress on the movement and potentially affect its accuracy. The ideal winding settings for a watch winder should be determined by the watchmaker or manufacturer.

Professional Watchmaker Intervention

While basic troubleshooting steps can resolve minor lagging issues, serious or persistent problems require the expertise of a qualified watchmaker. A watchmaker possesses the specialized tools, knowledge, and experience to diagnose and repair intricate mechanical timepieces effectively.

Watchmaker Procedures

A watchmaker will conduct a thorough inspection of the watch to identify the root cause of the lagging. This process typically involves the following procedures:

- Cleaning: Accumulated dust, dirt, and oil residue can hinder the smooth operation of watch components. A professional cleaning removes these contaminants, ensuring optimal performance.

- Lubrication: Proper lubrication is crucial for reducing friction and wear between moving parts. Watchmakers use specialized lubricants designed for delicate mechanisms, ensuring smooth and efficient movement.

- Component Replacement: If the lagging is caused by a worn-out or damaged component, such as a spring, gear, or balance wheel, the watchmaker will replace it with a genuine or compatible part.

- Regulation: Watchmakers use specialized tools to adjust the timing of the watch, ensuring accuracy and consistency. This process involves fine-tuning the balance wheel and hairspring, which regulate the watch’s rate.

Cost Considerations

The cost of watch repairs and maintenance varies widely depending on the watch’s brand, model, complexity, and the nature of the repair. Simple cleaning and lubrication services might cost around $50-$100, while component replacements or more complex repairs can range from $100 to several hundred dollars.

In some cases, repairs for high-end watches could even exceed $1000.

It’s essential to choose a reputable watchmaker with experience in servicing the specific type of watch you own. Consulting multiple watchmakers for estimates and recommendations is advisable before proceeding with any repairs.

5. Preventative Maintenance for Mechanical Watches: How To Fix Mechanical Watch Lagging Behind

Preventative maintenance is crucial for ensuring the longevity and accuracy of your mechanical watch. By following a regular schedule of cleaning, lubrication, and careful handling, you can minimize wear and tear and prevent potential complications that could lead to lagging.

Regular Cleaning

Regular cleaning is essential for removing dust, dirt, and debris that can accumulate within the watch movement and hinder its smooth operation. This is especially important for watches that are frequently worn or exposed to harsh environments.

- Frequency:Ideally, a mechanical watch should be cleaned every 2-3 years, depending on the level of wear and exposure to environmental factors. However, watches worn daily or in dusty environments may require more frequent cleaning.

- Parts to Clean:The most critical parts to clean are the movement, including the gears, wheels, and escapement, as well as the dial, hands, and crystal.

- Cleaning Methods:Cleaning a mechanical watch is a delicate process that should be performed by a qualified watchmaker. They use specialized cleaning solutions and tools to remove dirt and debris without damaging the delicate components.

Lubrication

Lubrication is essential for reducing friction between the moving parts of the watch movement, ensuring smooth operation and preventing wear and tear.

- Types of Lubricants:Watchmakers use specialized lubricants formulated for the specific conditions within a watch movement. These lubricants are typically oil-based and designed to resist oxidation and evaporation over time.

- Frequency:Lubrication is typically performed during a full service, which is recommended every 3-5 years, depending on the watch’s usage and the type of lubricant used.

- Impact of Incorrect Lubrication:Using the wrong type of lubricant or applying it incorrectly can lead to gumming, clogging, and premature wear of the watch movement.

Careful Handling

Proper handling is essential to prevent damage and wear and tear on your mechanical watch.

- Avoid Extreme Temperatures:Exposure to extreme temperatures, both hot and cold, can affect the watch’s performance and potentially damage the movement. Avoid leaving your watch in direct sunlight, near heat sources, or in freezing temperatures.

- Avoid Magnetic Fields:Mechanical watches are sensitive to magnetic fields, which can disrupt the movement’s operation and cause inaccurate timekeeping. Keep your watch away from strong magnets, such as those found in speakers, cell phones, and medical equipment.

- Avoid Shocks and Vibrations:Mechanical watches are delicate instruments that can be damaged by shocks and vibrations. Avoid dropping your watch or exposing it to excessive jolting or shaking.

Storage

Proper storage is essential for protecting your mechanical watch when it’s not being worn.

- Humidity Control:Excessive humidity can lead to corrosion and damage to the watch movement. Store your watch in a dry, well-ventilated environment.

- Winding Techniques:If your watch is not being worn, it’s essential to wind it regularly to keep the movement lubricated and prevent damage from prolonged inactivity. Follow the manufacturer’s recommendations for winding frequency and technique.

- Watch Winders:Watch winders are devices that automatically wind your watch, ensuring it remains powered and in good working order when not being worn.

Common Mechanical Watch Problems

Regular maintenance is crucial for ensuring the longevity and accuracy of your mechanical watch. Over time, wear and tear can lead to various problems that may affect its performance. Understanding these common issues and their potential causes can help you address them promptly and keep your watch running smoothly.

Common Mechanical Watch Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Lagging | The watch runs slower than its stated rate. |

|

| Stopping | The watch completely stops running. |

|

| Fast Running | The watch runs faster than its stated rate. |

|

| Noisy Movement | The watch makes unusual noises, such as ticking, grinding, or clicking. |

|

| Power Reserve Issues | The watch’s power reserve is shorter than expected or the watch runs out of power quickly. |

|

Watch Movement Types

The heart of any mechanical watch is its movement, the intricate system of gears, springs, and levers that power the timekeeping functions. Understanding the different types of watch movements is crucial for appreciating the complexity and nuances of these timepieces.

This section will delve into the three primary categories of mechanical watch movements: hand-wound, automatic, and chronograph, highlighting their unique characteristics and potential issues.

Hand-Wound Movements

Hand-wound movements, as the name suggests, rely on the user to manually wind the mainspring. This type of movement is typically found in vintage watches and high-end luxury timepieces, prized for their simplicity and the tactile experience of winding the watch.

The mainspring, a coiled spring housed within the watch, stores energy when wound. As the spring unwinds, it releases energy that drives the gears and ultimately moves the hands. The winding process is typically done by turning a crown on the side of the watch.Hand-wound movements are known for their precision and durability.

They are also relatively easy to maintain, as they have fewer moving parts than automatic movements. However, they require regular winding, typically every day or two, depending on the watch’s power reserve.

Automatic Movements

Automatic movements, also known as self-winding movements, are designed to wind themselves using the natural motion of the wearer’s wrist. This type of movement is the most popular choice for modern mechanical watches, offering convenience and practicality.The automatic winding mechanism is a complex system of gears and a rotor, a weighted component that rotates freely within the movement.

As the wearer moves their wrist, the rotor spins, winding the mainspring. The winding process is continuous, ensuring the watch stays powered even when not actively worn.Automatic movements are often considered more practical than hand-wound movements, as they require less user intervention.

However, they are also more complex and can be more susceptible to issues like wear and tear. They also tend to be more expensive than hand-wound movements.

Chronograph Movements

Chronograph movements are specialized mechanical movements that include a stopwatch function. These movements are typically used in sports watches, racing watches, and other timepieces that require precise timing capabilities.Chronograph movements feature a dedicated chronograph mechanism, typically consisting of a column wheel and a clutch.

The column wheel controls the starting, stopping, and resetting of the chronograph function, while the clutch connects the chronograph hand to the movement’s main train.Chronograph movements are the most complex type of mechanical watch movement. They are known for their precision and versatility but are also more expensive and require more specialized maintenance than other movement types.

Table Comparing Watch Movement Types

| Feature | Hand-Wound | Automatic | Chronograph |

|---|---|---|---|

| Winding Mechanism | Manual winding | Automatic winding | Manual or automatic winding |

| Power Reserve | Typically 30-48 hours | Typically 30-48 hours | Typically 30-48 hours |

| Complexity | Simple | Complex | Very complex |

| Cost | Less expensive | More expensive | Most expensive |

| Maintenance | Easy | Moderate | Difficult |

8. Impact of Environment

The environment in which a mechanical watch operates plays a crucial role in its accuracy, longevity, and overall performance. Various environmental factors, including temperature, humidity, magnetic fields, and even dust, can significantly affect the delicate components of a mechanical watch.

Understanding these environmental influences is essential for ensuring the optimal functioning and preservation of your timepiece.

8.1. Temperature Sensitivity

Temperature fluctuations can significantly affect the rate of a mechanical watch’s oscillator. The balance wheel, the heart of a mechanical watch, oscillates at a specific frequency, which is directly influenced by the elasticity of the hairspring. Changes in temperature affect the elasticity of the hairspring, altering the balance wheel’s oscillation frequency.

This results in variations in the watch’s accuracy, with the watch running faster in warmer temperatures and slower in colder temperatures.Extreme temperatures, both hot and cold, can have detrimental effects on the components of a mechanical watch. High temperatures can lead to the expansion of metal parts, potentially causing friction and wear.

Lubrication can also become less effective at high temperatures, leading to increased friction and wear. Conversely, cold temperatures can cause the metal components to contract, potentially leading to increased stiffness and reduced lubrication efficiency. In extreme cases, the oil in a mechanical watch can even freeze, causing the watch to stop entirely.To mitigate the effects of temperature fluctuations, some mechanical watches incorporate “temperature compensation” mechanisms.

These mechanisms typically utilize a bimetallic strip, which consists of two metals with different thermal expansion coefficients. As the temperature changes, the bimetallic strip bends, adjusting the effective length of the hairspring to compensate for the temperature-induced changes in its elasticity.

This helps to maintain a more consistent rate of oscillation despite variations in temperature.

8.2. Humidity and Moisture

High humidity can significantly impact the performance of a mechanical watch, primarily through corrosion and lubrication degradation. Moisture in the air can condense on the watch’s components, leading to the formation of rust or other forms of corrosion, particularly on metal parts.

This corrosion can hinder the smooth operation of the watch’s mechanism, potentially leading to malfunctions or even complete failure. Additionally, high humidity can accelerate the breakdown of the oil used for lubrication, reducing its effectiveness and leading to increased friction and wear.Exposing a mechanical watch to water or condensation can have serious consequences.

Water ingress can damage the delicate internal components, leading to corrosion, rust, and malfunctions. In extreme cases, water damage can even cause the watch to stop entirely.It’s important to understand the difference between water resistance and waterproofness in watches. Water resistance indicates that a watch can withstand a certain amount of water pressure for a specified duration.

However, it doesn’t mean the watch is impervious to water damage. Waterproofness, on the other hand, implies a higher level of water resistance, usually indicated by a specific rating, such as ATM (atmospheres) or bar (bars). To determine a watch’s water resistance rating, standardized testing methods are used.

These methods involve subjecting the watch to various pressures and durations of immersion in water to assess its ability to withstand water ingress. However, it’s important to note that even waterproof watches have limitations, and prolonged exposure to water or submersion beyond their rated depth can still lead to damage.

8.3. Magnetic Fields

Magnetic fields can significantly affect the operation of a mechanical watch, particularly the balance wheel and hairspring. These components are made of ferromagnetic materials, which are susceptible to magnetic forces. When exposed to a magnetic field, the balance wheel and hairspring can become magnetized, altering their natural oscillation frequency.

This can lead to a significant change in the watch’s accuracy, causing it to run faster or slower than intended.Several types of magnetic fields can pose a threat to a mechanical watch, including those generated by household appliances such as refrigerators, washing machines, and even smartphones.

Medical equipment, such as MRI machines, also produces strong magnetic fields that can severely damage a mechanical watch.To protect mechanical watches from magnetic fields, some watchmakers utilize anti-magnetic materials in their construction. These materials, such as soft iron or mu-metal, have high magnetic permeability, effectively shielding the watch’s internal components from external magnetic fields.

However, it’s important to note that even anti-magnetic watches have limitations, and prolonged exposure to extremely strong magnetic fields can still affect their performance.

8.4. Storage and Protection

Proper storage is crucial for preserving the accuracy, longevity, and overall condition of a mechanical watch. The optimal storage environment for a mechanical watch involves maintaining a stable temperature and humidity, minimizing exposure to light, and protecting it from dust and other contaminants.A watch box or case provides a safe and controlled environment for storing a mechanical watch.

These containers can help regulate temperature and humidity, protect the watch from dust and scratches, and prevent accidental damage.When handling a mechanical watch, it’s important to exercise caution to minimize the risk of damage or scratches. Avoid dropping the watch or subjecting it to sudden impacts.

When winding the watch, use gentle and consistent pressure to avoid overwinding or damaging the winding mechanism.Watch winders are devices designed to keep a mechanical watch wound and running while it’s not being worn. They can be beneficial in maintaining the watch’s accuracy and lubrication, especially for watches with power reserves of less than 48 hours.

However, it’s important to choose a reputable watch winder that is compatible with your watch’s movement and winding mechanism.

8.5. Environmental Hazards

Various environmental hazards can damage a mechanical watch, including dust, dirt, chemicals, and even extreme temperature fluctuations. Dust and dirt can accumulate on the watch’s components, hindering their smooth operation and potentially leading to wear and tear. Chemicals, such as perfumes, cleaning agents, and even certain types of cosmetics, can damage the watch’s case, crystal, and even the internal components.To protect a mechanical watch from these hazards, it’s essential to take preventative measures.

Store the watch in a dust-free environment, such as a watch box or case. Avoid wearing the watch in dusty or dirty environments, and clean it regularly with a soft, dry cloth. Avoid exposing the watch to chemicals, and if accidental contact occurs, rinse the watch thoroughly with clean water.Regular cleaning and maintenance are crucial for ensuring the longevity and performance of a mechanical watch.

A professional watchmaker can perform a thorough cleaning and inspection, ensuring that the watch is free of dust, dirt, and other contaminants. They can also lubricate the moving parts, ensuring smooth operation and reducing wear and tear.

Choosing a Watchmaker

When your mechanical watch requires attention beyond basic troubleshooting, finding a skilled and reputable watchmaker is crucial. A qualified watchmaker can diagnose complex issues, perform delicate repairs, and ensure your timepiece functions optimally for years to come. Choosing the right watchmaker is a significant decision, as it directly impacts the longevity and accuracy of your cherished timepiece.

Researching Watchmaker Credentials and Experience

It is essential to research a watchmaker’s qualifications and experience before entrusting them with your valuable watch.

- Certification and Training:Look for watchmakers certified by reputable organizations, such as the American Watchmakers-Clockmakers Institute (AWCI) or the British Horological Institute (BHI). These certifications demonstrate a commitment to professional standards and technical proficiency.

- Experience and Specialization:Consider the watchmaker’s experience with specific watch brands, movements, and complications. For instance, a specialist in vintage pocket watches might be better equipped to handle delicate repairs than a general watchmaker.

- Reputation and Reviews:Read online reviews and testimonials from previous customers to gauge a watchmaker’s reputation for quality workmanship, communication, and customer service.

Benefits of Choosing a Specialist Watchmaker

Specialists often possess in-depth knowledge and experience with specific types of watches or movements.

- Complex Complications:For watches with intricate complications like chronographs, moon phases, or perpetual calendars, a specialist watchmaker with experience in these areas is highly recommended. They understand the delicate mechanisms and can perform repairs with precision and expertise.

- Vintage and Antique Watches:Antique and vintage watches often require specialized knowledge and techniques for restoration and repair. A watchmaker specializing in these areas will have the expertise to handle delicate movements, sourcing original parts, and maintaining the watch’s historical integrity.

- Specific Brands:Some watchmakers specialize in particular brands, such as Rolex, Patek Philippe, or Omega. These specialists often have access to specialized tools and parts, as well as a deep understanding of the brand’s history and manufacturing processes.

Understanding Watch Accuracy

The accuracy of a mechanical watch is a critical aspect of its performance, indicating how closely it aligns with the actual time. Watch accuracy is typically measured in seconds per day (SPD), reflecting the deviation from the standard timekeeping reference.

A positive SPD value indicates the watch is running fast, while a negative value indicates it is running slow.

Factors Affecting Watch Accuracy

The accuracy of a mechanical watch is influenced by a complex interplay of factors, including the design and quality of the movement, the materials used, and the surrounding environment.

A lagging mechanical watch often needs a simple adjustment. If the watch is running slow, you might need to wind it more frequently or consider getting it serviced by a watchmaker. While you’re dealing with timing issues, you might be wondering how old do cats have to be to get fixed – a completely different topic, but just as important! Once you’ve taken care of your watch, you can focus on other important matters like your furry friend’s health.

- Movement Type:The type of mechanical movement significantly impacts accuracy. High-end mechanical movements, like those found in luxury watches, often employ more sophisticated designs and higher-quality components, resulting in superior accuracy.

- Quality of Components:The precision and quality of individual components within the movement, such as the balance wheel, hairspring, and escapement, directly affect the watch’s timekeeping performance. Higher-quality components, often crafted from materials like high-grade steel or alloys, contribute to improved accuracy.

- Environmental Conditions:Temperature, humidity, and magnetic fields can all affect the performance of a mechanical watch. Fluctuations in temperature can cause the movement to expand or contract, impacting its rate. Humidity can lead to corrosion, while magnetic fields can interfere with the balance wheel’s operation.

Typical Accuracy Ranges

The accuracy of mechanical watches can vary considerably depending on the factors mentioned above. Here are some typical accuracy ranges for different types of mechanical watches:

- Entry-Level Watches:These watches typically have accuracy ranges of -20 to +40 SPD. They may experience greater fluctuations in accuracy due to less sophisticated movements and components.

- Mid-Range Watches:Watches in this category often exhibit accuracy within -10 to +20 SPD. They generally incorporate more refined movements and components, leading to improved timekeeping.

- Luxury Watches:High-end mechanical watches from renowned brands often boast accuracy within -5 to +5 SPD, or even better. These watches utilize meticulously crafted movements, high-quality materials, and advanced technologies to achieve exceptional precision.

It is important to note that these are just general ranges, and individual watches within a particular category may deviate from these figures. Factors such as the age of the watch, its maintenance history, and the individual user’s habits can all impact accuracy.

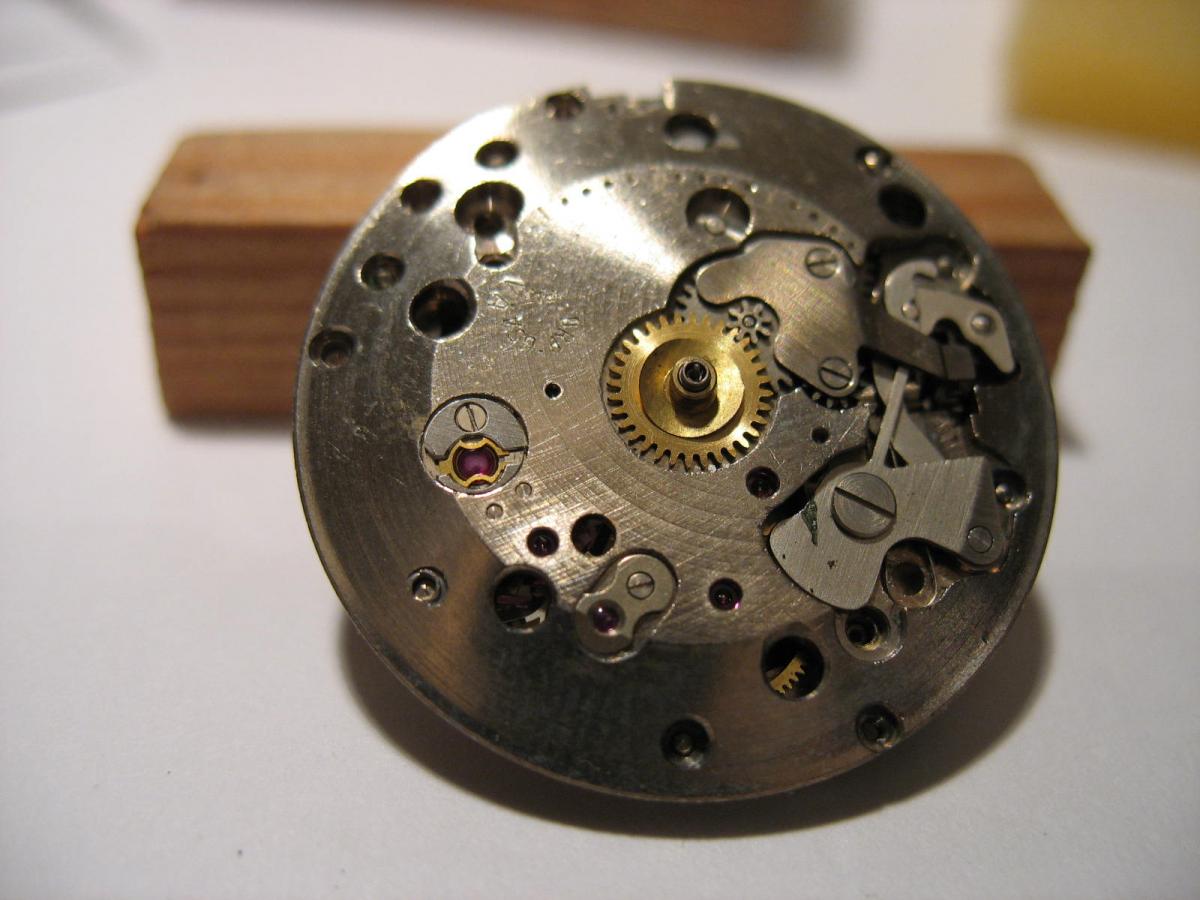

Watch Components and their Function

Understanding the intricate components within a mechanical watch is essential for appreciating its complexity and ensuring its longevity. Each part plays a crucial role in the watch’s operation, contributing to its accuracy and functionality. This section delves into the common components of a mechanical watch, exploring their functions, potential wear and tear, and the timing issues that can arise from these wear patterns.

Common Mechanical Watch Components

| Component Name | Function | Description | Common Wear and Tear | Timing Issues |

|---|---|---|---|---|

| Mainspring | Stores and releases energy | A tightly wound spring that provides the power for the watch’s operation. It releases energy gradually through the gear train. | Weakening, breakage, or loss of elasticity | Lagging, stopping, or inconsistent timekeeping |

| Barrel | Houses and controls the mainspring | A cylindrical component that contains the mainspring and regulates its unwinding. It prevents the mainspring from overwinding. | Worn bearings, damage to the winding mechanism | Lagging, inconsistent timekeeping, or winding issues |

| Gear Train | Transmits power and regulates speed | A series of gears that transfer the energy from the mainspring to the escapement. Each gear has a specific number of teeth, determining the gear ratio and the watch’s speed. | Worn teeth, friction, or misalignment | Lagging, speeding up, or inconsistent timekeeping |

| Escapement | Regulates the release of energy | A mechanism that controls the release of energy from the mainspring in controlled pulses, allowing the watch to keep time accurately. | Worn parts, friction, or misalignment | Lagging, speeding up, or stopping |

| Balance Wheel | Oscillates at a specific frequency | A weighted wheel that oscillates back and forth at a precise frequency, determining the watch’s rate. | Worn bearings, damage to the balance spring, or imbalance | Lagging, speeding up, or inconsistent timekeeping |

| Balance Spring | Controls the balance wheel’s oscillation | A spiral spring attached to the balance wheel, providing the restoring force that makes the wheel oscillate. | Weakening, breakage, or loss of elasticity | Lagging, speeding up, or inconsistent timekeeping |

| Hairspring | Regulates the balance wheel’s oscillation | A delicate spring that controls the balance wheel’s oscillation, ensuring it oscillates at the correct frequency. | Weakening, breakage, or loss of elasticity | Lagging, speeding up, or inconsistent timekeeping |

| Escape Wheel | Interacts with the escapement | A wheel with teeth that engage with the escapement, allowing the energy to be released in controlled pulses. | Worn teeth, friction, or misalignment | Lagging, speeding up, or stopping |

| Lever | Controls the escapement’s operation | A small lever that interacts with the escape wheel, controlling the release of energy from the mainspring. | Worn parts, friction, or misalignment | Lagging, speeding up, or stopping |

| Pallet Fork | Interacts with the escape wheel | A forked component that interacts with the escape wheel, controlling the release of energy and the balance wheel’s oscillation. | Worn parts, friction, or misalignment | Lagging, speeding up, or stopping |

| Crown | Winding and setting the watch | A knob on the watch case that allows the user to wind the mainspring and set the time. | Worn parts, damage to the winding mechanism | Winding issues, difficulty setting the time |

| Stem | Connects the crown to the movement | A shaft that connects the crown to the winding mechanism and the setting mechanism. | Worn parts, damage to the winding mechanism | Winding issues, difficulty setting the time |

| Case | Protects the movement | The outer shell of the watch, providing protection for the delicate internal components. | Scratches, dents, or water damage | No direct impact on timing but can affect the watch’s overall functionality |

| Crystal | Protects the dial | The transparent cover over the watch dial, providing protection from scratches and impacts. | Scratches, cracks, or damage | No direct impact on timing but can affect the watch’s overall appearance |

| Dial | Displays the time | The face of the watch, featuring the hands and hour markers to display the time. | Scratches, fading, or damage to the hands | No direct impact on timing but can affect the watch’s readability |

Key Questions Answered

What is the difference between a hand-wound and an automatic watch?

A hand-wound watch requires you to manually wind the mainspring using the crown. An automatic watch winds itself through the movement of your wrist, using a rotor that spins with your arm’s motion.

How often should I service my mechanical watch?

It’s generally recommended to service your mechanical watch every 3-5 years. However, this can vary depending on the watch’s age, usage, and environment.

Can I use any type of oil for my mechanical watch?

No, you should only use specialized watch oils that are formulated for the delicate components of a mechanical watch. Using the wrong type of oil can damage the movement.

What are the signs of a watch that needs to be serviced?

Signs include lagging, running fast, stopping, making unusual noises, or having a reduced power reserve.

How do I know if I should attempt to fix my watch myself or take it to a professional?

If you are not experienced with watch repair, it’s best to take your watch to a professional. Attempting to fix it yourself could cause further damage.