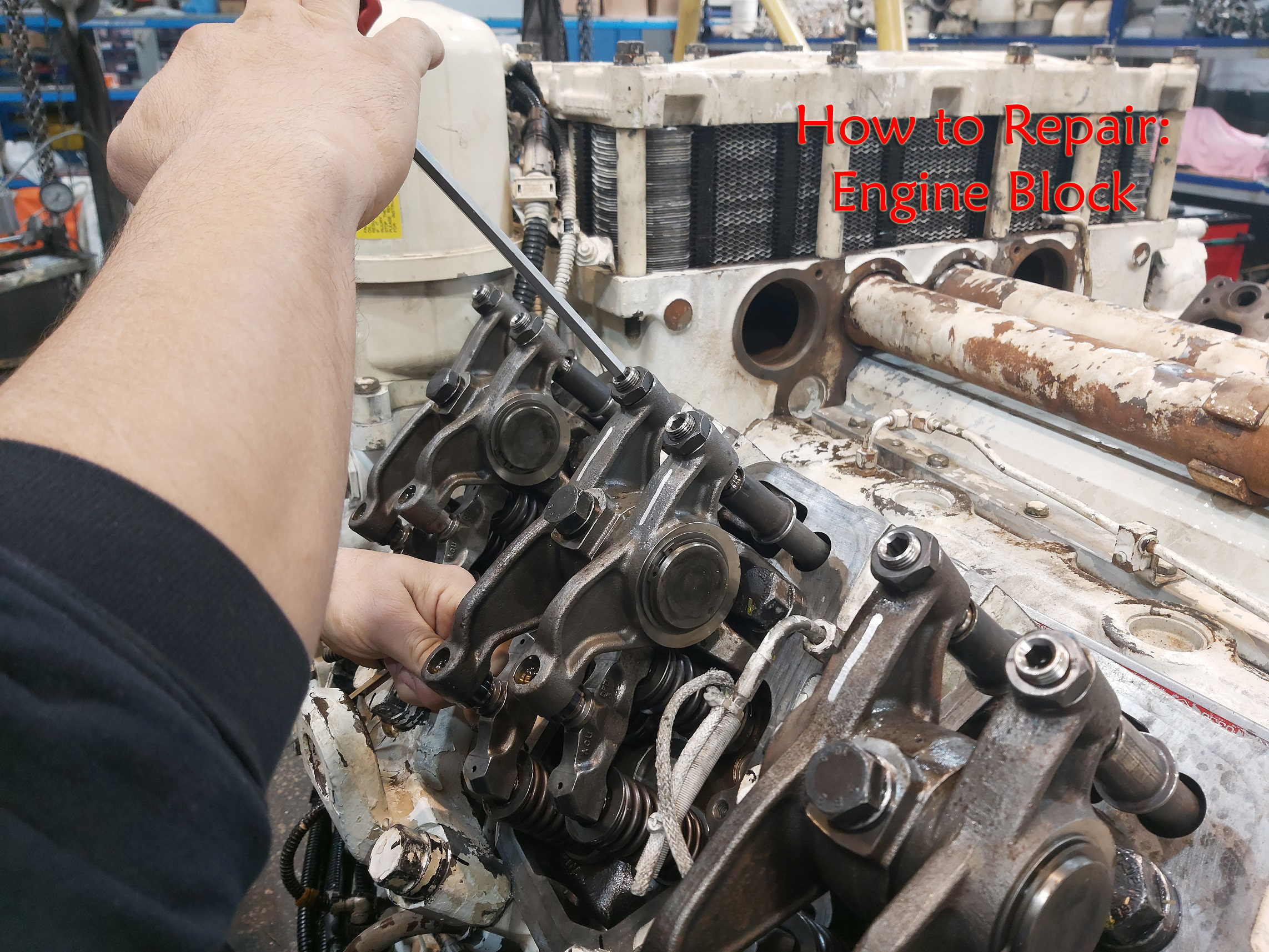

How to fix a cracked engine block? It’s a question that sends shivers down the spine of any car owner. This potentially serious issue can arise from various factors, including overheating, improper maintenance, and mechanical stress. Ignoring a cracked engine block can lead to catastrophic engine failure, leaving you stranded and facing hefty repair bills.

Understanding the causes, assessing the damage, and exploring repair options are crucial steps in addressing this critical automotive problem.

This guide delves into the intricacies of cracked engine blocks, providing a comprehensive overview of the issue. From identifying the different types of cracks to exploring various repair methods, we aim to equip you with the knowledge to make informed decisions regarding your vehicle’s health.

We’ll also address preventative measures, cost considerations, and common mistakes to avoid, ensuring you have a clear understanding of this complex topic.

Understanding Engine Block Cracks

An engine block crack is a serious issue that can lead to significant engine damage and costly repairs. Understanding the different types of cracks, their causes, and potential consequences is crucial for diagnosing and addressing the problem effectively.

Types of Engine Block Cracks

Engine block cracks can manifest in various forms, each with its own characteristics and implications.

- Hairline Cracks:These are small, thin cracks that are often difficult to detect visually. They may not immediately cause significant problems but can worsen over time, leading to coolant leaks or structural weakness.

- Stress Cracks:These cracks develop due to excessive stress on the engine block, often caused by overheating or improper maintenance. They are typically larger than hairline cracks and can cause significant damage if left untreated.

- Casting Defects:These cracks are present from the manufacturing process and can be caused by flaws in the casting material or improper cooling during production. They can lead to engine failure if not addressed promptly.

Causes of Engine Block Cracks

Engine block cracks are often the result of a combination of factors.

- Overheating:When an engine overheats, the metal expands and contracts rapidly, creating stress on the engine block. This can lead to cracks, especially if the overheating is severe or prolonged.

- Improper Maintenance:Neglecting routine maintenance, such as oil changes and coolant flushes, can contribute to engine block cracks. Insufficient lubrication or coolant can cause excessive wear and tear, leading to cracks.

- Mechanical Stress:Excessive mechanical stress, such as sudden acceleration or heavy loads, can also cause engine block cracks. This is particularly common in engines that are heavily modified or used in demanding applications.

Consequences of Ignoring an Engine Block Crack

Ignoring an engine block crack can have serious consequences.

- Coolant Leaks:Cracks can allow coolant to leak into the engine, leading to overheating and potential engine damage.

- Oil Leaks:Cracks can also allow oil to leak out of the engine, leading to lubrication problems and engine failure.

- Structural Weakness:Cracks can weaken the engine block, making it more susceptible to further damage.

- Engine Failure:In severe cases, an engine block crack can lead to complete engine failure, requiring a costly replacement.

Repair Options

Repairing a cracked engine block can be a complex process, and the best method depends on the severity of the crack, the material of the block, and the overall condition of the engine. Several repair methods exist, each with its own advantages, disadvantages, and cost implications.

Engine Block Repair Methods

Repairing a cracked engine block involves restoring the structural integrity of the block to prevent further damage and ensure proper engine function. Common repair methods include:

| Method | Advantages | Disadvantages | Cost |

|---|---|---|---|

| Welding |

|

| $200

|

| Sleeving |

|

| $500

|

| Epoxy |

|

| $50

|

Welding

Welding involves using a high-heat process to fuse metal together, effectively closing the crack in the engine block. This method is often used for larger cracks and is generally considered a strong and durable repair.

However, welding requires specialized equipment and expertise to ensure proper execution, and the heat can potentially distort the block if not applied correctly.

Sleeving

Sleeving is a repair method that involves inserting a metal sleeve into the damaged cylinder bore. This process restores the cylinder bore to factory specifications, ensuring proper piston movement and sealing. Sleeving is a durable and long-lasting repair but requires specialized equipment and expertise.

It can be an expensive option and may not be suitable for all engine blocks.

Epoxy

Epoxy is a type of adhesive that can be used to seal small cracks in engine blocks. It is a simple and relatively inexpensive repair method, making it a popular choice for minor cracks. However, epoxy is not as strong or durable as welding or sleeving and may not be suitable for high-pressure areas.

Additionally, epoxy repairs have a limited lifespan and may need to be replaced over time.

4. Welding Repair

Welding is a common and often effective method for repairing cracks in engine blocks. It involves fusing metal together using heat and filler material, creating a solid bond to restore the structural integrity of the block. However, welding engine blocks requires specialized skills, knowledge, and equipment, and it’s crucial to understand the specific considerations involved.

4.1. Welding a Cracked Engine Block

The suitability of welding as a repair method depends on several factors, including the type and location of the crack, the material of the engine block, and the overall condition of the engine.

- Crack Type and Location:Cracks in engine blocks can vary in their nature and location. Common types include hairline cracks, transverse cracks, and longitudinal cracks. The location can be in the cylinder head, the block itself, or the cylinder walls.

- Engine Block Material:Engine blocks are typically made of cast iron or aluminum. Cast iron is a more common material, known for its strength and durability, but it can be challenging to weld due to its tendency to crack further under stress. Aluminum is lighter and more readily machinable, but it requires specialized welding techniques and materials.

4.2. Welding Materials and Techniques

The choice of welding materials and techniques is crucial for a successful engine block repair. The material of the engine block dictates the type of welding filler rod or wire required, and the welding process itself must be tailored to ensure proper fusion and minimize stress on the repaired area.

- Welding Materials:

- Cast Iron:For cast iron engine blocks, specialized cast iron filler rods are used. These rods contain alloys that match the composition of the cast iron, ensuring a strong and compatible weld.

- Aluminum:Aluminum engine blocks require aluminum welding wire. These wires are formulated to melt at temperatures compatible with aluminum, creating a robust and corrosion-resistant weld.

- Welding Techniques:

- TIG Welding (Gas Tungsten Arc Welding):TIG welding is a precise technique that uses a non-consumable tungsten electrode and an inert gas shield to create a high-quality weld. It’s often preferred for aluminum engine blocks due to its ability to produce clean, smooth welds.

- MIG Welding (Gas Metal Arc Welding):MIG welding uses a consumable wire electrode and a shielding gas to create a continuous weld. It’s suitable for both cast iron and aluminum engine blocks, but it may require more skill and practice to achieve optimal results.

- Arc Welding:Arc welding is a more traditional technique that uses a consumable electrode to create an arc that melts the base metal and filler material. While it’s less precise than TIG or MIG welding, it can be used for cast iron engine blocks, especially for thicker repairs.

4.3. Preparing the Engine Block for Welding

Proper preparation is essential for a successful weld. This includes cleaning the engine block surface around the crack, creating a weld preparation area, and ensuring the surrounding metal is properly preheated.

- Cleaning the Engine Block:

- Removing Contaminants:The engine block surface must be thoroughly cleaned to remove any contaminants, such as oil, grease, dirt, or rust. This can be done using a wire brush, a grinding wheel, or a combination of cleaning agents.

- Importance of Cleaning:Contaminants can hinder the welding process, leading to poor adhesion, porosity, and potential weld failure.

- Creating a Weld Preparation Area:

- Beveling the Edges:The edges of the crack should be beveled to create a V-shaped groove. This allows for better penetration of the weld material and ensures a stronger bond.

- Creating a Clean Surface:The area around the crack should be ground smooth to provide a clean surface for welding. This helps prevent the weld from being contaminated by irregularities or debris.

4.4. Technical Document

Welding a Cracked Engine Block: A Comprehensive Guide1. IntroductionThis document Artikels the process of welding a cracked engine block, providing a detailed guide for technicians and enthusiasts. It covers the essential steps, materials, and techniques involved in repairing a cracked engine block, ensuring a successful and durable outcome.

2. Crack Identification and Assessment* Type and Location:Determine the type of crack (hairline, transverse, longitudinal) and its location (cylinder head, block, cylinder walls).

Severity

Assess the severity of the crack, considering its length, depth, and any associated damage.

Engine Block Material

Identify the material of the engine block (cast iron, aluminum). 3. Welding Materials and Techniques* Cast Iron:Use specialized cast iron filler rods, ensuring compatibility with the base material. Consider TIG or arc welding techniques.

Aluminum

Use aluminum welding wire for optimal bonding. TIG welding is generally preferred due to its precision. 4. Engine Block Preparation* Cleaning:Thoroughly clean the engine block surface around the crack using appropriate tools and cleaning agents to remove contaminants.

Weld Preparation Area

Bevel the edges of the crack to create a V-shaped groove, and grind the surrounding area smooth for a clean welding surface.

Preheating

If necessary, preheat the engine block to the recommended temperature for the specific material and welding process. 5. Welding Process* Setting Up:Configure the welding equipment according to the chosen technique and materials.

Welding Procedure

Follow the specific welding procedure for the chosen technique, ensuring proper bead formation, penetration, and cooling.

Layering

For thicker cracks, apply multiple layers of weld material, allowing each layer to cool before proceeding to the next. 6. Inspection and Evaluation* Visual Inspection:After welding, visually inspect the weld for any defects, such as cracks, porosity, or incomplete fusion.

Testing

Consider conducting non-destructive testing (e.g., dye penetrant, magnetic particle) to evaluate the weld’s integrity. 7. Post-Weld Finishing and Cleanup* Cleaning:Clean the weld area to remove any slag or spatter.

Machining

If necessary, machine the weld area to restore the original dimensions and surface finish. 8. Considerations* Stress Relief:Consider performing stress relief heat treatment after welding to minimize residual stress and potential cracking.

Engine Testing

After welding, thoroughly test the engine to ensure the repair is successful and the engine operates properly. 9. Safety Precautions* Protective Gear:Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a welding mask.

Ventilation

Ensure adequate ventilation during the welding process to minimize exposure to fumes.

Fire Safety

Take necessary precautions to prevent fires, especially when working with flammable materials. 10. ConclusionWelding a cracked engine block requires specialized skills, knowledge, and equipment. By following the guidelines Artikeld in this document, technicians and enthusiasts can effectively repair cracked engine blocks, restoring their structural integrity and extending their lifespan.

Table:| Step | Description ||—|—|| 1 | Identify the crack type and location || 2 | Choose appropriate welding materials and techniques || 3 | Prepare the engine block for welding || 4 | Execute the welding process || 5 | Inspect and evaluate the weld || 6 | Post-weld finishing and cleanup |

Sleeving Repair

Sleeving is a common and effective method for repairing cracked engine blocks. It involves inserting a metal sleeve into the damaged cylinder bore, effectively restoring the cylinder’s integrity and allowing for continued engine operation.

Types of Sleeves

Different types of sleeves are available, each offering distinct advantages and disadvantages.

- Cast Iron Sleeves:These sleeves are durable and resistant to wear, making them a popular choice for high-performance engines. They are typically thicker than other types of sleeves, providing additional strength and rigidity.

- Steel Sleeves:Steel sleeves offer excellent strength and wear resistance, similar to cast iron. However, they can be more expensive to manufacture and install.

- Aluminum Sleeves:Aluminum sleeves are lightweight and offer good thermal conductivity, making them suitable for engines where weight reduction is crucial. However, they may not be as durable as cast iron or steel sleeves.

Procedure for Installing a Sleeve

The installation process involves several steps, ensuring a secure and functional sleeve:

- Prepare the Cylinder Bore:The cracked cylinder bore must be thoroughly cleaned and prepared to receive the sleeve. This may involve machining the bore to remove any damaged material and ensure a precise fit for the sleeve.

- Insert the Sleeve:The sleeve is carefully inserted into the prepared cylinder bore, ensuring a snug fit. The sleeve may be pressed into place or installed using a special tool that expands the sleeve to secure it within the bore.

- Align and Secure the Sleeve:Once the sleeve is in place, it must be aligned and secured to prevent movement. This may involve using special tools or techniques to ensure the sleeve is properly positioned within the bore.

- Finish the Bore:After the sleeve is installed and secured, the cylinder bore is finished to ensure a smooth and precise surface for the piston rings. This typically involves honing the bore to remove any irregularities and create a uniform surface.

Epoxy Repair

Epoxy repair is a temporary solution for engine block cracks. It involves using a strong adhesive to seal the crack and prevent coolant or oil leaks. While epoxy repair can be a quick and inexpensive fix, it’s crucial to understand its limitations and potential drawbacks.

Advantages of Epoxy Repair

Epoxy repair offers several advantages:

- Cost-effective:Epoxy is relatively inexpensive compared to other repair methods, making it an attractive option for budget-conscious individuals.

- Quick and easy:Epoxy repair can be done relatively quickly, often within a few hours, allowing you to get your vehicle back on the road sooner.

- Accessible:Epoxy is readily available at most automotive supply stores, making it easy to find and purchase.

Disadvantages of Epoxy Repair

Epoxy repair also has its share of drawbacks:

- Temporary fix:Epoxy is not a permanent solution and will eventually fail, requiring a more permanent repair in the future.

- Limited strength:Epoxy is not as strong as metal, and the repaired area may be prone to further cracking or damage under stress.

- Heat resistance:Epoxy can soften or degrade at high temperatures, potentially leading to leaks or failure under engine operating conditions.

- Not suitable for all cracks:Epoxy repair is not effective for large or deep cracks, as it may not provide sufficient strength to hold the crack closed.

Applying Epoxy to a Cracked Engine Block

Applying epoxy to a cracked engine block requires careful preparation and application:

- Clean the crack:Thoroughly clean the crack with a wire brush or sandpaper to remove any dirt, oil, or debris.

- Degrease the area:Use a degreaser to remove any remaining oil or contaminants from the crack and surrounding area.

- Apply epoxy:Mix the epoxy according to the manufacturer’s instructions and apply it to the crack, ensuring complete coverage.

- Clamp the crack:Use clamps to hold the crack closed while the epoxy cures. This helps to ensure a strong and secure bond.

- Allow the epoxy to cure:Follow the manufacturer’s curing time recommendations. Do not start the engine until the epoxy has fully cured.

7. Preventative Measures

While understanding how to repair an engine block crack is essential, preventing such issues in the first place is the most effective approach. This section will explore various preventative measures that can significantly reduce the risk of engine block cracks.

7.1. Engine Block Crack Prevention, How to fix a cracked engine block

Preventing engine block cracks involves adopting a combination of driving practices and regular maintenance routines. Here are five practical tips to minimize the risk:

- Avoid Aggressive Acceleration and Braking:Sudden bursts of speed and abrupt braking put significant stress on the engine block, increasing the likelihood of cracks, especially in older engines. Smooth acceleration and gentle braking help distribute stress evenly.

- Maintain Consistent Engine Temperature:Rapid temperature fluctuations, such as those caused by prolonged idling or excessive high-speed driving, can weaken the engine block. Aim for consistent engine operating temperatures within the recommended range.

- Proper Warm-up and Cool-Down:Before putting your engine under load, allow it to warm up properly. Similarly, after driving, let the engine cool down for a few minutes before switching it off. This prevents thermal shock that can lead to cracks.

- Regular Oil Changes:Dirty oil can clog engine passages and restrict proper lubrication, increasing friction and heat. Regular oil changes ensure optimal lubrication, reducing wear and tear on the engine block.

- Avoid Overloading the Engine:Towing heavy loads or carrying excessive weight can strain the engine, leading to cracks. Be mindful of the engine’s capacity and avoid overloading it.

7.2. Regular Maintenance and Inspections

Regular maintenance and inspections are crucial for preventing engine block cracks. Scheduled servicing ensures early detection of potential problems, allowing for timely repairs and preventing them from escalating. This includes inspecting for signs of coolant leaks, oil leaks, and any unusual noises or vibrations that could indicate engine block damage.

7.3. High-Quality Coolant and Overheating

Using high-quality engine coolant and avoiding overheating are critical for preventing engine block cracks. Here’s a breakdown of their importance:

| High-Quality Coolant | Overheating |

|---|---|

| Provides optimal heat transfer, preventing excessive temperatures. | Exposes the engine block to extreme heat, weakening its structure and increasing the risk of cracks. |

| Contains corrosion inhibitors that protect the engine block from rust and corrosion. | Can lead to warping, distortion, and cracking of the engine block due to thermal stress. |

| Maintains proper pressure within the cooling system, preventing boiling and overheating. | Causes the engine block to expand and contract rapidly, potentially leading to cracks. |

8. Considerations for Replacement

Replacing an engine block is a major undertaking, often requiring significant investment and technical expertise. It’s a decision that should not be taken lightly, and a thorough assessment of the situation is crucial before proceeding.

When to Replace the Engine Block

Determining whether to replace an engine block is a complex decision influenced by several factors, including the extent of damage, the cost of repair, and the overall condition of the engine. Here’s a breakdown of key considerations:

- Severe Cracks:If the engine block has large, deep cracks that extend across critical load-bearing areas, especially near the cylinder bores or the water jacket, a replacement is often the most practical solution. These cracks compromise the structural integrity of the block, leading to potential catastrophic failures and safety hazards.

- Extensive Damage:If the engine block has suffered significant damage, such as a broken cylinder head or a warped block, a replacement might be more cost-effective than attempting a repair. The repair process could involve extensive machining and rebuilding, potentially exceeding the cost of a new or used engine block.

- Engine Wear and Tear:If the engine is nearing the end of its service life and has accumulated significant wear and tear, a replacement engine block could be a more sensible option than rebuilding the existing one. This is especially true if the engine has experienced repeated repairs or has accumulated a high mileage.

A new engine block offers a fresh start, potentially providing years of reliable service.

- Availability of Parts:If the engine block is an older model or a rare variant, finding replacement parts for a repair might be challenging and expensive. In such cases, a replacement engine block might be the more practical solution, ensuring readily available parts and a smoother repair process.

- Cost-Benefit Analysis:A thorough cost-benefit analysis should be conducted before deciding on a replacement engine block. Consider the cost of a new or used engine block, the cost of labor, and the potential cost of future repairs. Compare these costs to the cost of rebuilding the existing engine block.

If the cost of replacing the engine block is significantly lower than the cost of a rebuild, it might be the more financially viable option.

Comparing Replacement vs. Rebuilding

Replacing an engine block is a significant investment, but it offers several advantages over rebuilding an existing block:

- New or Refurbished Components:A replacement engine block typically comes with new or refurbished components, ensuring optimal performance and longevity. This eliminates the uncertainty associated with using older or worn-out parts from the original engine.

- Reduced Risk of Future Issues:Replacing the engine block minimizes the risk of future issues related to wear and tear or pre-existing damage. It provides a fresh start, potentially extending the life of the vehicle and reducing the likelihood of costly repairs in the future.

- Improved Performance:A new or refurbished engine block can offer improved performance compared to a rebuilt engine block. This is due to the use of newer materials, advanced manufacturing techniques, and the elimination of wear and tear on existing components.

However, rebuilding an existing engine block can be a more cost-effective option in certain circumstances:

- Lower Initial Cost:Rebuilding an existing engine block typically involves lower initial costs compared to replacing the entire block. This is because you are reusing existing components and minimizing the need for new parts.

- Preserving Original Engine:Rebuilding an existing engine block allows you to preserve the original engine, potentially maintaining its historical value or sentimental significance. This can be important for classic cars or vehicles with unique engine specifications.

- Customizability:Rebuilding an existing engine block provides an opportunity for customization. You can upgrade components, improve performance, or modify the engine to meet specific needs. This flexibility is not available with a replacement engine block.

Factors to Consider When Choosing a Replacement Engine Block

Selecting a replacement engine block requires careful consideration to ensure compatibility with the vehicle and meet performance expectations. The following table Artikels key factors to consider:

| Factor | Description | Considerations |

|---|---|---|

| Material | The material used in the engine block affects its strength, durability, and weight. Common materials include cast iron, aluminum, and composite materials. | Cast iron offers durability and heat resistance, but it’s heavier. Aluminum is lighter and offers better heat dissipation, but it’s less durable. Composite materials offer a balance of strength, weight, and heat resistance. |

| Displacement | The displacement of the engine block determines its power output and fuel efficiency. It’s measured in liters or cubic inches. | The displacement should match the original engine or be within a compatible range. A larger displacement engine can provide more power, but it might affect fuel efficiency. |

| Power Output | The power output of the engine block is measured in horsepower or kilowatts. It indicates the engine’s ability to generate power. | Consider the power output required for the vehicle’s intended use. A higher power output can provide faster acceleration and better towing capabilities. |

| Compatibility | The engine block should be compatible with the vehicle’s existing systems, such as the cooling system, fuel system, and electrical system. | Ensure the engine block has the correct mounting points, oil pan configuration, and connections for the cooling system, fuel injectors, and sensors. Incompatibility can lead to performance issues, overheating, or even damage to the vehicle. |

| Warranty | Some replacement engine blocks come with warranties, providing protection against defects or failures. | Consider the duration and coverage of the warranty. A longer warranty provides peace of mind and protects against potential costs associated with repairs or replacements. |

Checklist for Inspecting a New Engine Block

Thoroughly inspecting a new engine block before installation is crucial to ensure it meets quality standards and is free from defects. Here’s a detailed checklist:

- Physical Condition:Inspect the engine block for any scratches, cracks, or signs of corrosion. These defects can compromise the block’s integrity and lead to premature failure.

- Manufacturing Quality:Examine the casting for any defects, such as air pockets, porosity, or uneven surfaces. These defects can weaken the block and affect its performance.

- Machining Tolerances:Check the cylinder bores, valve seats, and other machined surfaces for proper tolerances. Improper tolerances can lead to oil leaks, valve problems, or engine misfires.

- Compatibility:Verify that the engine block is the correct model, year, and engine code for your vehicle. Ensure that the block has the correct mounting points, oil pan configuration, and connections for the cooling system, fuel injectors, and sensors.

- Accessories:Check if the engine block includes any accessories, such as the oil pan, timing cover, or water pump. These components might be sold separately, so it’s essential to verify their inclusion.

- Cleaning and Inspection:Thoroughly clean the engine block before installation to remove any debris, dirt, or oil residue. This ensures a clean and debris-free environment for installation and reduces the risk of contamination. Inspect the cleaned block for any hidden defects or damage that might have been obscured by dirt or oil.

Common Mistakes to Avoid

Repairing a cracked engine block is a complex process that requires precision and expertise. Even with the right tools and techniques, certain common mistakes can lead to further damage or a less than ideal repair. Understanding these mistakes and how to avoid them is crucial for ensuring a successful and durable engine block repair.

Inadequate Cleaning

Proper cleaning of the cracked area is crucial for a successful repair. If the crack is not cleaned thoroughly, debris, oil, or coolant can remain trapped in the crack, preventing the welding or epoxy from bonding effectively.

Inadequate cleaning can result in a weak repair, leading to leaks or further cracks in the engine block.

Fixing a cracked engine block is a complex task that often involves specialized welding or replacement. However, before resorting to such drastic measures, it’s essential to ensure the issue isn’t a simple leak. Just like a leaking toilet can be frustrating even after replacing the flapper, a seemingly cracked engine block might have a hidden culprit.

If you’re facing a leaking engine, it’s wise to consult this guide on fixing a toilet leaking even with a new flapper for a similar troubleshooting approach. This could help you identify a potential issue that might be causing the leak, saving you from unnecessary repairs.

To avoid this mistake:

- Use a wire brush or a specialized cleaning tool to remove any rust, dirt, or other contaminants from the crack.

- Apply a degreaser to the area and allow it to sit for a few minutes before wiping it clean with a clean cloth.

- Consider using a high-pressure air hose to blow out any remaining debris.

Incorrect Welding Technique

Welding a cracked engine block requires specialized techniques and equipment. Improper welding can result in a weak repair, distort the engine block, or even create new cracks.

Using the wrong welding technique can weaken the repair, distort the engine block, or even create new cracks.

To avoid this mistake:

- Use a qualified welder with experience in repairing engine blocks.

- Ensure the welding equipment is calibrated correctly and the welding rods are appropriate for the engine block material.

- Follow the manufacturer’s instructions for welding procedures and preheating the engine block.

Improper Epoxy Application

Epoxy repairs are often used for minor cracks in engine blocks. However, improper application can lead to a weak repair that can fail under pressure.

Incorrect epoxy application can lead to a weak repair that fails under pressure, causing leaks or further damage.

To avoid this mistake:

- Use a high-quality epoxy specifically designed for engine block repairs.

- Follow the manufacturer’s instructions carefully regarding mixing ratios, application time, and curing time.

- Ensure the epoxy is applied evenly and completely fills the crack.

Insufficient Curing Time

After applying welding or epoxy, it’s crucial to allow sufficient time for the repair to cure completely. Insufficient curing time can result in a weak repair that can fail under pressure.

Insufficient curing time can lead to a weak repair that fails under pressure, resulting in leaks or further damage.

To avoid this mistake:

- Follow the manufacturer’s instructions regarding curing time for the welding or epoxy used.

- Allow the repair to cure in a controlled environment, avoiding extreme temperatures or humidity.

- Consider using a heat lamp or other methods to accelerate the curing process, if recommended by the manufacturer.

Case Studies: Cracked Engine Blocks: How To Fix A Cracked Engine Block

Examining real-world scenarios involving cracked engine blocks provides valuable insights into the effectiveness and cost of various repair methods. This section delves into three case studies, highlighting different causes of engine block cracks, the repair options employed, and their long-term implications.

Case Study 1: Overheating-Induced Crack

A car engine block cracked due to overheating caused by a faulty thermostat, preventing proper coolant circulation.

Repair Methods

- Welding the crack: A skilled welder used a specialized welding process, often employing TIG (Gas Tungsten Arc Welding) with a filler metal compatible with the engine block material (typically cast iron or aluminum). The process involves cleaning the crack, preheating the area to prevent warping, and carefully depositing the filler metal to bridge the gap.

This method is often used for smaller cracks and can be cost-effective compared to replacing the engine block.

- Replacing the engine block: The owner opted for a new engine block, ensuring a complete replacement and eliminating any potential for future issues related to the crack. This method guarantees a pristine engine block but comes with a higher price tag.

Analysis

- Welding: The welding repair proved effective in restoring the engine block’s integrity. It offered a more economical solution compared to replacing the engine block. However, the long-term durability of the weld depended on the skill of the welder and the quality of the welding process.

If the weld was not properly executed, it could lead to future cracks or leaks.

- Replacement: Replacing the engine block provided a guaranteed solution, eliminating any concerns about the previous crack. However, it incurred a significant expense, potentially exceeding the value of the vehicle, especially for older cars.

Long-Term Outcomes

- Welding: The welded engine block continued to function for several years, but the owner had to monitor the weld for any signs of leakage or weakening. Regular maintenance was essential, including coolant flushes and inspections of the weld area.

The long-term lifespan of the welded engine block was uncertain and depended on the quality of the repair.

- Replacement: The new engine block provided a reliable solution, eliminating the risk of further issues related to the crack. It ensured a longer lifespan for the engine, with the expectation of normal wear and tear over time. The owner could enjoy peace of mind knowing the engine was fully restored.

Case Study 2: Faulty Cooling System Crack

A truck engine block developed a crack due to a malfunctioning cooling system pump, causing inadequate coolant circulation and leading to overheating.

Repair Methods

- Epoxy Repair: A specialized epoxy resin designed for engine block repairs was applied to the crack. The epoxy was mixed according to the manufacturer’s instructions and carefully applied to the cleaned crack. The epoxy hardened, creating a strong bond that sealed the crack and prevented leaks.

This method is often considered a temporary solution for smaller cracks and may not be suitable for all situations.

- Remanufactured Engine Block: The owner opted for a remanufactured engine block, which had been thoroughly inspected, repaired, and tested to meet original specifications. This method provided a reliable and cost-effective alternative to a brand-new engine block.

Analysis

- Epoxy Repair: The epoxy repair provided a quick and cost-effective solution for a small crack. However, the epoxy’s long-term durability was questionable. Exposure to high temperatures and engine vibrations could potentially cause the epoxy to fail over time, leading to leaks and further damage.

- Remanufactured Engine Block: The remanufactured engine block offered a balance between cost and reliability. It provided a restored engine block at a lower price than a brand-new one. The remanufactured block came with a warranty, ensuring peace of mind and addressing potential concerns about the repair.

Long-Term Outcomes

- Epoxy Repair: The epoxy repair initially addressed the leak, but the engine eventually developed further cracks, requiring a more permanent solution. The owner had to replace the engine block sooner than anticipated due to the limitations of the epoxy repair.

- Remanufactured Engine Block: The remanufactured engine block provided a reliable and long-lasting solution. The truck experienced smooth operation and did not exhibit any signs of issues related to the previous crack. The remanufactured block provided a cost-effective alternative to a new engine block, extending the truck’s lifespan and ensuring continued performance.

Case Study 3: Mechanical Failure Crack

A motorcycle engine block cracked due to a mechanical failure involving a connecting rod.

Repair Methods

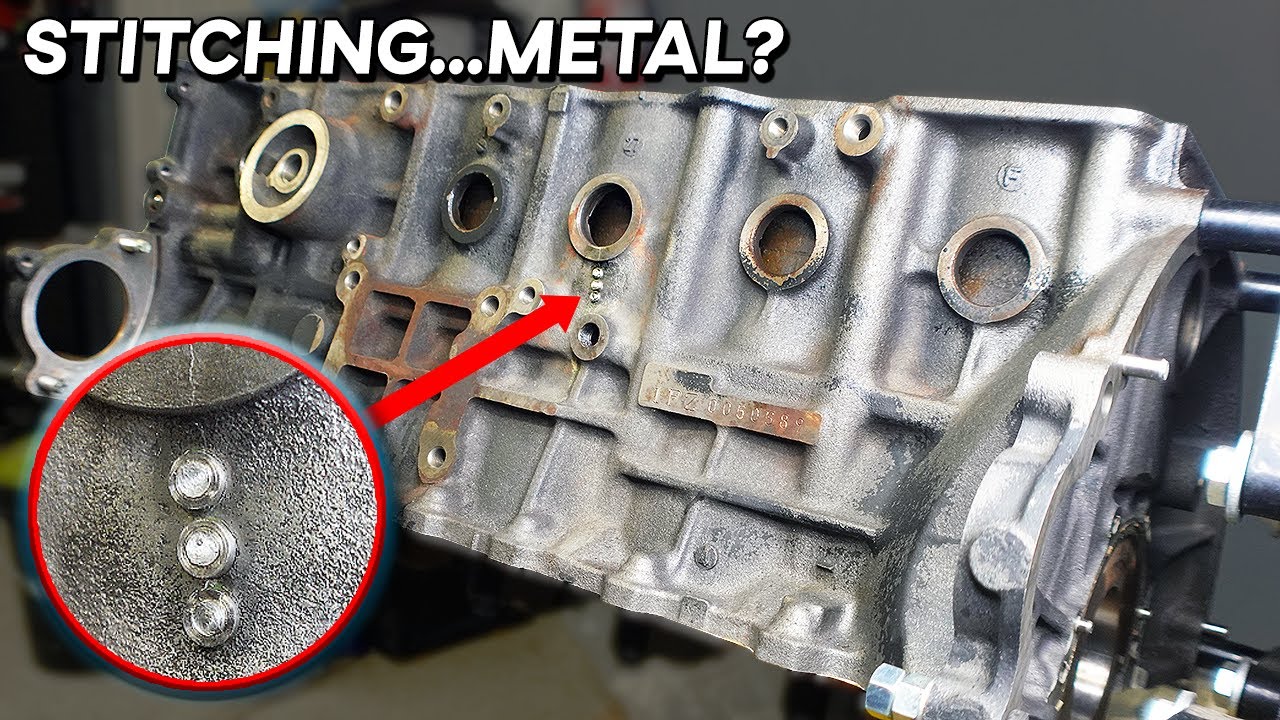

- Metal Bonding Compound: A specialized metal bonding compound was used to repair the crack. The compound was applied to the cleaned crack, creating a strong bond that restored the engine block’s structural integrity. This method is often used for smaller cracks and may not be suitable for larger cracks or those involving significant stress.

- New Engine Block: The owner chose to replace the engine block with a new one, ensuring a completely restored engine with optimal performance. This method provided a guaranteed solution, eliminating any concerns about the previous crack and offering a fresh start for the motorcycle.

Analysis

- Metal Bonding Compound: The metal bonding compound provided a quick and relatively inexpensive solution for a small crack. However, the long-term durability of the compound was uncertain, as it might not withstand the extreme stresses experienced in a motorcycle engine.

The compound’s effectiveness could be compromised by high temperatures and vibrations, potentially leading to future failures.

- New Engine Block: Replacing the engine block provided a reliable and long-lasting solution, ensuring optimal performance for the motorcycle. The new engine block offered peace of mind, eliminating any concerns about the previous crack and guaranteeing a smooth and trouble-free riding experience.

However, it came at a significant cost, potentially exceeding the value of the motorcycle.

Long-Term Outcomes

- Metal Bonding Compound: The metal bonding compound initially addressed the leak, but the engine eventually developed further cracks, requiring a more permanent solution. The owner had to replace the engine block sooner than anticipated due to the limitations of the compound’s durability.

- New Engine Block: The new engine block provided a reliable and long-lasting solution. The motorcycle experienced smooth operation and did not exhibit any signs of issues related to the previous crack. The new block provided a guaranteed solution, extending the motorcycle’s lifespan and ensuring continued performance.

Frequently Asked Questions

Having a cracked engine block can be a stressful experience, and many questions might arise regarding its causes, symptoms, and repair options. This section addresses common questions about cracked engine blocks, providing you with the information you need to understand the situation and make informed decisions.

Causes of Cracked Engine Blocks

Engine blocks are susceptible to cracking due to various factors, and understanding these causes can help prevent future issues.

| Question | Answer |

|---|---|

| What are the common causes of cracked engine blocks? | Overheating, improper maintenance, wear and tear, and manufacturing defects are the primary causes of cracked engine blocks. |

| Can overheating cause a cracked engine block? | Yes, overheating can lead to thermal stress on the engine block, causing it to expand and contract unevenly, which can result in cracks. |

| How does improper maintenance contribute to engine block cracks? | Neglecting regular maintenance tasks, such as coolant flushes and oil changes, can lead to excessive wear and tear on the engine, ultimately contributing to cracks. |

| Can wear and tear cause cracks in an engine block? | Yes, prolonged use and wear and tear can weaken the engine block material, making it more susceptible to cracks, especially in areas prone to stress. |

| Are there any manufacturing defects that can lead to cracked engine blocks? | Yes, manufacturing defects, such as imperfections in the casting process, can create weak points in the engine block that are prone to cracking. |

Symptoms of a Cracked Engine Block

Recognizing the symptoms of a cracked engine block is crucial for timely diagnosis and repair.

| Question | Answer |

|---|---|

| What are the symptoms of a cracked engine block? | Symptoms of a cracked engine block can include coolant leaks, engine knocking, loss of power, and overheating. |

| How can I identify a coolant leak from a cracked engine block? | Coolant leaks from a cracked engine block are often characterized by a sweet-smelling liquid dripping from the engine or a noticeable decrease in coolant levels in the reservoir. |

| What causes engine knocking in a cracked engine block? | Engine knocking can occur when the engine block cracks, allowing combustion gases to leak into the cooling system, which can cause the engine to run rough and produce a knocking sound. |

| How does a cracked engine block affect engine power? | A cracked engine block can cause a loss of engine power due to combustion gases escaping through the crack, leading to a reduction in engine compression. |

| Why does an engine overheat with a cracked engine block? | Overheating can occur when a cracked engine block allows coolant to leak out, resulting in insufficient cooling for the engine. |

Repair Options for a Cracked Engine Block

Repairing a cracked engine block involves various methods, each with its own advantages and limitations.

| Question | Answer |

|---|---|

| What are the repair options for a cracked engine block? | Repair options for a cracked engine block include welding, sleeving, and replacement. |

| How does welding repair a cracked engine block? | Welding involves using a welding torch to melt metal and fill in the crack, creating a solid bond. |

| What is sleeving repair for a cracked engine block? | Sleeving involves inserting a metal sleeve into the cylinder bore to repair a crack that extends into the cylinder. |

| When is replacing an engine block the best option? | Replacing the engine block is often the best option for severe cracks, extensive damage, or when the cost of repair exceeds the value of the vehicle. |

| Can I use epoxy to repair a cracked engine block? | While epoxy can be used as a temporary fix for small cracks, it is not a permanent solution and should be considered only as a temporary measure. |

User Queries

What are the symptoms of a cracked engine block?

A cracked engine block can manifest in several ways. Common symptoms include coolant leaks, especially if the crack is in the water jacket area. You might also notice engine knocking or a rattling sound, particularly when the engine is cold.

A loss of power or a drop in engine performance can also be indicative of a cracked engine block. In some cases, you might see white smoke coming from the exhaust, which is a sign of coolant entering the combustion chamber.

If you suspect a cracked engine block, it’s essential to seek professional diagnosis as soon as possible.

Can a cracked engine block be repaired?

Yes, a cracked engine block can be repaired, but the repair method depends on the severity of the crack and the material of the engine block. Common repair options include welding, sleeving, and epoxy repair. Welding is often used for hairline cracks, while sleeving is a more robust solution for larger cracks.

Epoxy repair is typically used as a temporary solution for minor cracks.

How much does it cost to repair a cracked engine block?

The cost of repairing a cracked engine block varies significantly depending on the repair method, the severity of the crack, and the location of the repair. Welding can be relatively affordable, while sleeving or replacing the engine block can be more expensive.

It’s essential to get quotes from multiple repair shops to compare costs and ensure you’re getting a fair price.

Is it better to repair or replace a cracked engine block?

The decision to repair or replace a cracked engine block depends on several factors, including the severity of the crack, the age and condition of the engine, and the overall cost of repair versus replacement. In some cases, repairing a cracked engine block may be a cost-effective solution, especially if the crack is minor.

However, if the crack is extensive or the engine is nearing the end of its lifespan, replacing the engine block or the entire engine might be a more practical option.